Beyond the Sheet: Why Syndanio vs. Mica Choice Can Save Your Furnace Coil

In an induction melting furnace, coil failure is rarely caused by copper quality alone. In most cases, the real culprit lies between the turns—the coil insulation sheet.

Choosing the right insulation material, especially between Syndanio insulation sheets and Mica insulation sheets, can significantly extend induction furnace coil life, improve electrical safety, and reduce unplanned shutdowns.

This blog goes beyond the datasheet to explain why Syndanio vs. Mica selection matters, how it impacts induction furnace performance, and which insulation is best for your melting application.

Why Coil Insulation Is Critical in Induction Furnaces

The induction furnace coil operates under extreme conditions:

- High-frequency AC current

- Intense electromagnetic flux

- Continuous thermal cycling

- Water-cooled copper conductors

- High mechanical stress during expansion

Without proper coil insulation sheets, furnaces face:

- Turn-to-turn short circuits

- Electrical leakage

- Coil overheating

- Reduced power efficiency

- Premature coil failure

That’s where Syndanio sheets and Mica sheets play a vital role.

What Is a Syndanio Insulation Sheet?

Syndanio is a phenolic laminated insulation sheet, manufactured using cotton fabric impregnated with phenolic resin.

Key Properties of Syndanio Sheets

- Excellent mechanical strength

- Good electrical insulation

- High impact and compression resistance

- Stable under continuous vibration

- Easy to machine and shape

Common Uses in Induction Furnaces

- Coil inter-turn insulation

- Coil support insulation

- Insulation between copper coil and yoke

- Structural electrical insulation components

What Is Mica Insulation Sheet?

Mica sheets are produced from natural mica flakes bonded with silicone or epoxy resin.

Key Properties of Mica Sheets

- Extremely high thermal resistance

- Excellent dielectric strength

- Superior performance in high-temperature zones

- Resistant to arc tracking

- Non-combustible material

Common Uses in Induction Furnaces

- High-temperature coil insulation

- Areas exposed to molten metal radiation

- Furnace zones requiring high dielectric strength

1. Preventing “Coil Squashing” (The Syndanio Advantage)

When a furnace is powered up, the electromagnetic field creates a physical force that tries to compress the coil turns together.

- The Risk: If you use a material that is too soft or thin (like basic Mica paper) in a large-scale furnace, the vibration and pressure can eventually cause the insulation to thin out or “cold flow.” Once the copper turns touch, you get a turn-to-turn short circuit.

- The Save: Syndanio is a rigid, cement-based structural board. It acts as a physical “stop.” By using Syndanio spacers, you ensure the gap between turns remains constant regardless of the magnetic pressure. This saves the coil from mechanical deformation.

2. Managing the “Thermal Wall” (The Mica Advantage)

The refractory lining between the molten metal and the copper coil is only a few inches thick.

- The Risk: In high-temperature melts (like steel or iron), the radiant heat can exceed the limits of organic or fiber-based insulators. If the insulation carbonizes (turns to char), it becomes conductive. Once it’s conductive, the electricity jumps the gap, causing an arc that melts a hole in your copper water-cooling tube.

- The Save: Mica is chemically stable at temperatures exceeding 1000°C. It won’t carbonize. By using Mica as a primary wrap, you create a “thermal shield” that prevents heat-induced electrical breakdown, saving your coil from a catastrophic water leak into the furnace.

3. Dealing with “Carbon Tracking”

Foundry environments are dirty. Graphite dust and metallic particles float in the air and settle on the coil.

- The Risk: Over time, these particles form a “bridge” across the insulation.

- The Save: Syndanio is prized for its high arc resistance. It is much harder for an electrical “track” to form across the surface of a Syndanio board than it is on many cheaper plastic or composite alternatives. Mica, being a natural mineral, also provides an inorganic surface that does not support the growth of electrical tracks.

Why the Wrong Insulation Choice Damages Furnace Coils

Many induction furnace coil failures occur because:

- Syndanio is used where mica is required

- Mica is used where mechanical strength is critical

- Insulation thickness is incorrectly selected

- Low-grade insulation sheets are installed

Common Failure Scenarios

- Coil turns cracking due to brittle mica

- Electrical breakdown due to overheating of syndanio

- Water leakage causing insulation degradation

- Increased furnace downtime and coil repair cost

Choosing the right insulation sheet prevents coil short circuits, power loss, and coil replacement expenses.

Which Insulation Sheet Should You Choose?

Choose Syndanio Sheet When:

- Mechanical support is required

- Coil movement and vibration are high

- Budget optimization is critical

- Furnace operates at moderate temperatures

Choose Mica Sheet When:

- Operating temperature is extremely high

- Furnace runs at higher power density

- Electrical insulation reliability is critical

- Coil exposure to radiant heat is severe

Best Practice:

Most modern induction furnaces use a combination of Syndanio + Mica insulation to balance mechanical strength and thermal protection.

Impact on Furnace Efficiency and Coil Life

Correct insulation selection results in:

- Longer induction furnace coil life

- Reduced maintenance cost

- Improved electrical efficiency

- Lower risk of sudden breakdown

- Better power factor stability

A small decision at the insulation stage can save lakhs in coil replacement costs over a furnace’s lifetime.

Conclusion: Insulation Is Not Just a Sheet—It’s Coil Protection

In induction melting systems, insulation sheets are not passive components. They actively protect the heart of the furnace—the coil.

Understanding the difference between Syndanio vs. Mica insulation sheets allows foundries and furnace manufacturers to make smart, performance-driven decisions.

Choosing the right insulation today ensures stable melting, safe operation, and long-term furnace reliability.

About Electro Power Enterprise

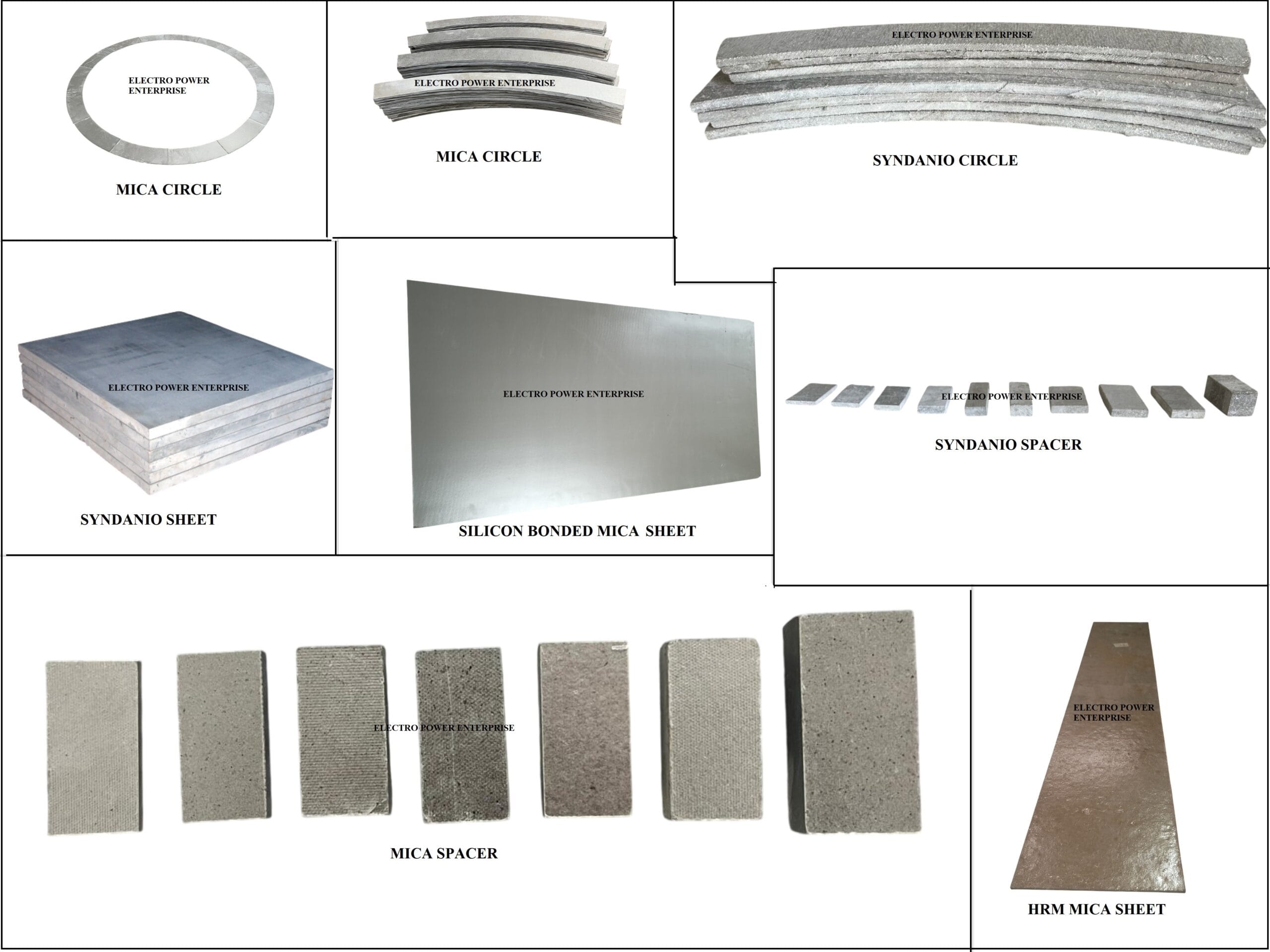

Electro Power Enterprise is a trusted manufacturer and supplier of induction furnace spare parts, including:

- Syndanio insulation sheets

- Mica insulation sheets

- Induction furnace coils

- FRP & Permali coil supports

- Chill blocks, copper components, and refractory solutions

Contact us for custom insulation solutions tailored to your furnace design.

Rajesh Baraiya, Founder of Electro Power Enterprise, is passionate about making induction furnaces run more efficiently and last longer. Backed by three decades of hands-on experience, He provides practical insights into Induction furnace spare parts, enabling industries to achieve higher efficiency and longer furnace life.