Industrial Machines Used in Induction Furnace Spare Parts Manufacturing

In the induction furnace industry, time is critical. Furnace stoppages directly affect metal production, manpower utilization, and delivery commitments. The ability to manufacture, repair, test, and dispatch induction furnace components quickly depends largely on the industrial machines available in the workshop.

At Electro Power Enterprise, these industrial machines are not just workshop equipment—they are the backbone of our speed, reliability, and consistency in induction furnace spare parts manufacturing.

Our machine-driven processes allow us to respond quickly to emergency breakdowns, manufacture custom furnace spare parts with accuracy, and dispatch material on time without compromising performance or safety. This capability directly improves furnace reliability at the customer’s site by reducing rework, preventing electrical and cooling failures, and ensuring components are installation-ready. This is what clearly differentiates Electro Power Enterprise from conventional induction furnace spare parts manufacturers—we don’t rely on shortcuts or outsourcing; we rely on precision machines, controlled processes, and speed that keeps our customers’ furnaces running.

This blog explains how each industrial machine is used in the induction furnace spare parts manufacturing and how its capability reduces lead time, enabling faster service and consistent material availability—clearly differentiating a professional induction furnace spare parts manufacturer from conventional suppliers.

1. Coil Winding Machine – Used for Induction Furnace Coil Manufacturing

The heart of any induction furnace is the induction coil, typically made from high-conductivity copper tubing.

The heart of any induction furnace is the induction coil, typically made from high-conductivity copper tubing.

The coil winding (bending) machine is used to wind copper tubes into precise induction furnace coils, which generate the electromagnetic field required for metal melting.

How It Makes the Process Faster

- Eliminates manual bending and repeated trial corrections

- Produces uniform coil turns in fewer production cycles

- Allows quick changeover between different furnace sizes

- Minimizes rejection and rework

Process Advantage

Coil winding machines ensure perfect circularity and consistent pitch, resulting in uniform magnetic field distribution and faster, more even metal heating.

As a result, induction furnace coils can be manufactured and supplied in significantly less time, which is crucial during coil failures or emergency furnace breakdowns.

2. Refractory Mixer & Vibrator Machine – Used for Furnace Refractory top & Bottom

This machine is used to prepare top and bottom refractory material by uniformly mixing cement, water, and stainless steel (SS) fiber.

This machine is used to prepare top and bottom refractory material by uniformly mixing cement, water, and stainless steel (SS) fiber.

The mixer ensures a homogenous blend, while the vibrator compacts the material to eliminate air pockets.

How It Speeds Up Lining Work

- Faster and more uniform mixing compared to manual methods

- Immediate vibration removes trapped air

- Faster readiness for lining installation

Process Advantage

Refractory top and bottom lining work is completed quickly and consistently, allowing furnaces to return to operation sooner and reducing downtime.

3. Pressing Machine – Used for Induction Furnace Yoke Assembly

The pressing machine compresses CRNGO and CRGO laminations to form induction furnace yokes, which guide magnetic flux and reduce electrical losses.

The pressing machine compresses CRNGO and CRGO laminations to form induction furnace yokes, which guide magnetic flux and reduce electrical losses.

How It Reduces Lead Time

- One-step lamination compression

- Eliminates slow manual stacking

- Produces ready-to-install yokes

Process Advantage

Induction furnace lamination yokes are manufactured and dispatched without delay, enabling faster furnace assembly and maintenance.

4. Power Pack (Hydraulic Power Pack) – Used for Pressing Copper Rope Inside Water-Cooled Cable Connections

In induction furnace systems, water-cooled cables transfer extremely high current from the power supply to the furnace coil. Inside each water-cooled cable, multi-strand copper rope must be firmly pressed into the copper terminal or connector to ensure maximum electrical contact.

In induction furnace systems, water-cooled cables transfer extremely high current from the power supply to the furnace coil. Inside each water-cooled cable, multi-strand copper rope must be firmly pressed into the copper terminal or connector to ensure maximum electrical contact.

The hydraulic power pack is used to press the copper rope inside the water-cooled cable connection, creating a dense, uniform, and vibration-resistant joint. This process is critical to:

The power pack applies precise and repeatable hydraulic pressure to compress the copper rope evenly inside the terminal, eliminating air gaps and loose strands.

How It Makes the Process Faster

- Faster pressing compared to manual hammering or bolting

- No repeated tightening or adjustment required

- Reduced rejection and rework

- Quick preparation of water-cooled cable

Process Advantage

This ensure every water-cooled cable connection is:

- Properly compacted

- Electrically efficient

- Mechanically secure

- Ready for high-current, continuous operation

5. Water Pressure & Flow Test Machine – Used for Cooling Circuit Validation

This machine checks blockage and leakage in induction furnace coils, yokes, change-over switches, top rings, and other cooling circuits.

This machine checks blockage and leakage in induction furnace coils, yokes, change-over switches, top rings, and other cooling circuits.

How It Accelerates Dispatch

- Instant leak and flow verification

- Prevents repeated dismantling

- Single-cycle testing before dispatch

Process Advantage

Cooling components are cleared immediately for installation, preventing coil overheating and allowing the furnace to operate at maximum power without tripping.

6. Lathe Machine – Used for Precision Machining of Induction Furnace Components

A lathe machine is used for precision turning, facing, and sizing of round and cylindrical components used in induction furnace systems. Many furnace spare parts require tight dimensional accuracy to ensure proper fitment, electrical contact, and mechanical stability.

A lathe machine is used for precision turning, facing, and sizing of round and cylindrical components used in induction furnace systems. Many furnace spare parts require tight dimensional accuracy to ensure proper fitment, electrical contact, and mechanical stability.

In induction furnace applications, the lathe machine is commonly used for:

- Machining copper terminals and connectors

- Machining coil stud union and other parts

- Turning busbar ends and contact surfaces

- Machining shafts, pins, and

- Finishing components used in water-cooled cable assemblies and furnace structures

How Electro Power Enterprise Uses the Lathe Machine

It is used to ensure that all critical furnace components meet exact dimensional and surface finish requirements before assembly or installation.

By machining parts in-house, we maintain:

- Accurate concentricity and alignment

- Smooth contact surfaces for electrical joints

- Precise tolerances for proper assembly

How It Makes the Process Faster

- Eliminates dependency on external machining vendors

- Enables immediate correction or resizing of parts

- Faster preparation of custom or urgent components

- Reduces waiting time during assembly and repair

Process Advantage

Accurately machined components ensure proper electrical contact, vibration-free assembly, and reduced mechanical stress. This directly improves the reliability of induction furnace spare parts and minimizes installation issues at the customer site.

7. Pipe Bending Machine – Used for SS Cooling Turns

The pipe bending machine fabricates stainless steel water turns used in induction furnace cooling systems and auxiliary piping.

The pipe bending machine fabricates stainless steel water turns used in induction furnace cooling systems and auxiliary piping.

How It Improves Speed

- Fast and accurate bending

- No manual correction required

- Ready-to-fit SS turns

Process Advantage

Cooling components are manufactured in-house and on time, even for urgent or breakdown-related requirements.

8. Argon Welding Machine – Used for Capacitor Repair & Aluminum Welding

Argon (TIG) welding provides clean, high-strength joints capable of withstanding pressure and electrical stress.

Argon (TIG) welding provides clean, high-strength joints capable of withstanding pressure and electrical stress.

The argon welding machine is used for:

- Repairing induction furnace capacitors

- Welding aluminum front covers

How It Saves Time

- Clean welds without post-finishing

- Faster capacitor repair cycles

- Reduced rework and rejection

Process Advantage

Induction furnace capacitors are repaired and dispatched quickly, significantly reducing furnace downtime.

9. High Voltage Tester – Used for Electrical Insulation Verification

This machine checks the insulation strength of various induction furnace components. This also help us to test the High Voltage Induction Furnace Capaitor

This machine checks the insulation strength of various induction furnace components. This also help us to test the High Voltage Induction Furnace Capaitor

How It Speeds Up Approval

- Immediate pass/fail results

- Eliminates long-duration trial testing

- Faster electrical clearance

Process Advantage

Components are dispatched electrically safe and ready for operation, without unnecessary delays.

10. CNC Router Machine – Used for Induction Furnace Insulation Components

The CNC router machine is used to drill holes, provide counters for coil supports, cut insulation sheets to customer-specific sizes, and manufacture mica insulation circles for top and bottom coil insulation.

The CNC router machine is used to drill holes, provide counters for coil supports, cut insulation sheets to customer-specific sizes, and manufacture mica insulation circles for top and bottom coil insulation.

It is commonly used for:

- Permali coil supports

- FRP flats

- Mica insulation circles (top & bottom)

- Custom insulation components

How It Reduces Turnaround Time

- High-speed automated machining

- No manual marking or drilling

- High repeatability and accuracy

Process Advantage

Custom insulation parts are produced within hours, supporting fast furnace assembly and service. These tools are also used to fabricate insulating sideboards made from syndanio or FRP materials.

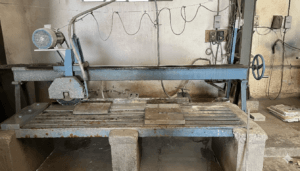

11. Cutter Machine – Used for Fast Insulation Sheet Cutting

The cutter machine is used to cut:

The cutter machine is used to cut:

- FRP sheets

- Syndanio sheets

- Mica sheets

- Insulation spacers as per customer requirement

How It Enables Faster Service

- Immediate cutting without outsourcing

- Same-day spacer fabrication

- Faster response during breakdowns

Process Advantage

Insulation materials are available exactly when needed, preventing service delays and extended furnace shutdowns.

12. High Power Drilling Machine – Used for Furnace Component Fabrication

This machine drills holes in:

This machine drills holes in:

- Furnace structural parts

- Insulation materials

- Coil supports and brackets

High-power drilling ensures heavy copper busbars are prepared accurately for bolting, preventing burrs, electrical arcing, and power loss.

How It Improves Speed

- High torque enables faster drilling

- Reduced manual effort

- Faster assembly cycles

Process Advantage

Fabrication and assembly processes move smoothly without bottlenecks.

13. Conductivity Testing Machine – Used for Copper Quality Control

This machine measures the purity and conductivity of copper used for:

This machine measures the purity and conductivity of copper used for:

- Induction furnace coils

- Busbars

- Yokes

Only EC-grade copper, suitable for high-frequency current, is approved. Higher conductivity means less energy loss and faster melting.

How It Saves Time

- Instant material verification

- No dependency on external laboratories

- Faster raw material approval

Process Advantage

Copper components move directly into production, ensuring faster delivery schedules.

14. CLR Testing Machine – Used for Electrical Matching of Furnace Systems

The CLR testing machine measures Capacitance, Inductance, and Resistance of furnace electrical components.

The CLR testing machine measures Capacitance, Inductance, and Resistance of furnace electrical components.

How It Speeds Up Commissioning

- Immediate electrical matching

- Eliminates trial-and-error tuning

- Faster readiness for installation

Process Advantage

Induction furnace electrical systems are delivered ready to operate, reducing commissioning and startup time.

Conclusion: Machine Capability Defines Speed & Reliability

In induction furnace spare parts manufacturing, machine capability directly determines speed and reliability. Workshops equipped with advanced industrial machines can:

- Respond faster to furnace breakdowns

- Manufacture and test components in-house

- Supply materials on time

- Reduce furnace downtime for customers

This is what clearly differentiates a professional induction furnace spare parts manufacturer from conventional suppliers relying on manual processes and outsourcing.

For immediate technical support or to request a quote, reach out to our team directly at +91 76003 43075 or email us at info@electropowerenterprise.in.

Rajesh Baraiya, Founder of Electro Power Enterprise, is passionate about making induction furnaces run more efficiently and last longer. Backed by three decades of hands-on experience, He provides practical insights into Induction furnace spare parts, enabling industries to achieve higher efficiency and longer furnace life.