Yoke Pad for Induction Furnace – Types, Materials, and Key Functions

Introduction

The Yoke Pad, also called a lamination insulation pad or shunt pad, is one of the most crucial insulation materials used in an induction furnace. It serves as both an electrical insulator and a mechanical cushion between the copper coil and the magnetic steel yoke (or shunt). A properly designed yoke pad ensures better electrical safety, mechanical stability, and energy efficiency of the furnace.

Types of Yoke Pad Materials

Yoke pads are manufactured using high-performance materials capable of withstanding high temperatures, voltage stress, and mechanical vibration. Based on their material composition, they are broadly divided into the following categories:

1. Mica-Based Yoke Pads (Hard Insulation Type)

Material Composition:

Made from mica sheets (e.g., silicon-bonded mica or HRM mica), often laminated with asbestos sheets or Nomex paper for enhanced strength.

Key Benefits:

- High Thermal Resistance: Handles continuous temperatures above 500°C, and up to 1000°C in certain grades.

- Excellent Electrical Insulation: Prevents arcing and electrical leakage in high-voltage areas.

- Rigid Structure: Provides strong mechanical support and alignment for the coil and yoke.

Applications:

Used in high-temperature induction furnaces requiring maximum dielectric strength and dimensional stability.

HRM Mica

2. Silicone-Based Yoke Pads (Flexible Insulation Type)

Material Composition:

Composed of high-grade silicone rubber or silicone-based composites, often reinforced with PTFE (Teflon) or Flexible mica.

Key Benefits:

- Superior Flexibility: Absorbs vibration and thermal expansion stresses effectively.

- Reliable Electrical Insulation: Maintains insulation performance under dynamic furnace conditions.

- Easy Installation: Soft and adaptable to minor surface irregularities.

Applications:

Best suited for furnaces that require vibration absorption, mechanical cushioning, and ease of assembly.

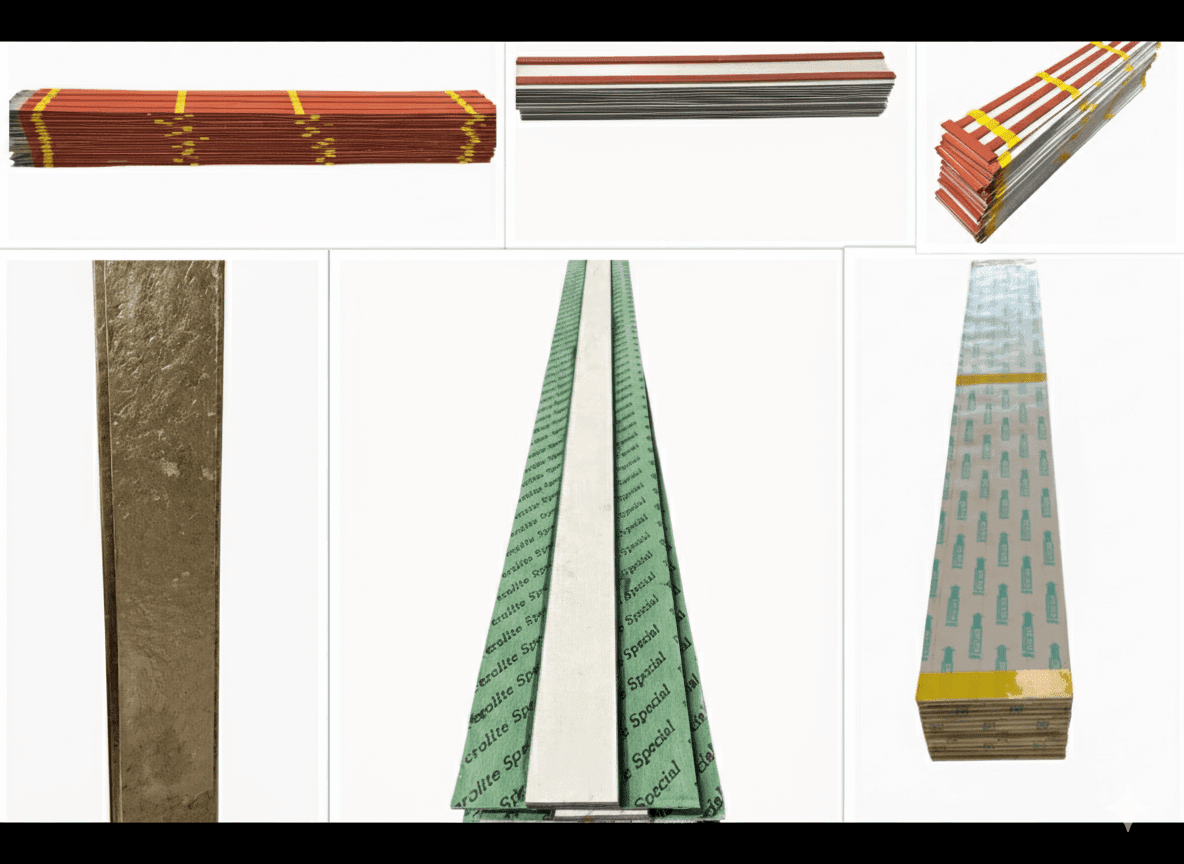

Silicon section + Flexible Mica

Silicon Rubber flat + PTFE +Mica

3. Composite or Layered Yoke Pads

Material Composition:

A hybrid structure that combines multiple materials such as Mica + Nomex + Asbestos or PTFE + Jointing Sheet + FRP.

Key Benefits:

- Balanced Performance: Mica provides heat resistance, while silicone or PTFE adds flexibility.

- Custom Design: Tailored for specific furnace conditions and insulation needs.

Applications:

Used where both thermal endurance and mechanical compliance are required.

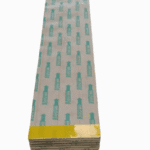

Nomex + Mica + Asbestos

FRP + Jointing Gasket + PTFE

Functions and Importance of Yoke Pads

The Yoke Pad performs three essential functions that contribute to furnace performance and longevity:

1. Electrical Insulation (Prevents Short Circuiting)

The yoke pad forms a dielectric barrier between the induction coil and magnetic yoke (laminated steel structure). This prevents electrical leakage, flashover, or short circuits, which could cause severe damage to the coil or power supply.

2. Mechanical Cushioning and Structural Stability

During operation, the induction coil experiences strong Lorentz forces and thermal expansion. The yoke pad acts as a shock absorber, protecting the coil from vibration, friction, and metal-to-metal contact, while maintaining a tight mechanical fit.

3. Thermal Protection and Heat Control

Though mainly electrical insulators, high-grade yoke pads also help reduce heat transfer from the molten metal zone to the yoke structure. This keeps the yoke cooler, improving magnetic efficiency and extending the life of coil insulation and laminations.

Common Yoke Pad Configurations in Industry

| Sr. No. | Material Composition | Used By / Application |

| 1 | Silicone Section + Flexible Mica | Electrotherm Furnaces |

| 2 | Silicone + PTFE + Mica | Electrotherm Furnaces |

| 3 | PTFE + Jointing Sheet + FRP | Inductotherm Furnaces |

| 4 | Mica + Nomex + Asbestos | Electrotherm & Megatherm Furnaces |

Custom Yoke/ Insulation pad

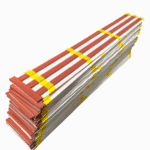

FRP + PTFE

FRP + Jointing Gasket

Silicon Rubber Flat + Silicon Bonded Mica + FRP

Conclusion

The yoke pad might be a small component, but its role in ensuring electrical safety, vibration control, and thermal management is critical to every induction furnace. Choosing the right yoke pad can significantly enhance furnace reliability, Furnace box life, and energy efficiency. If you’re looking for high-quality Silicon, PTFE or Mica based yoke pads.

Contact Electro Power Enterprise– a trusted Induction Furnace Spare Parts Supplier in India.

Rajesh Baraiya, Founder of Electro Power Enterprise, is passionate about making induction furnaces run more efficiently and last longer. Backed by three decades of hands-on experience, He provides practical insights into Induction furnace spare parts, enabling industries to achieve higher efficiency and longer furnace life.