Water-Cooled Cables in Induction Furnaces – Types, Function, and Common Failures

Water-cooled cables play a critical role in the performance and safety of induction furnaces. These flexible copper conductors carry high current from the power supply panel to the furnace coil while maintaining low electrical losses and safe operating temperatures. Understanding their design, function, and maintenance can help extend cable life and improve overall furnace efficiency.

What Are Water-Cooled Cables?

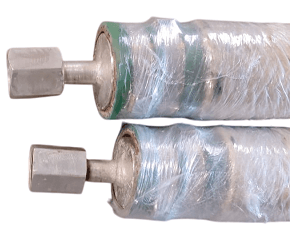

Water-cooled cables are high-current, flexible copper cables with an internal water-cooling system. They are specifically designed for induction melting and heating furnaces, where high electrical current and heat are continuously generated.

The copper conductor is made of multiple fine strands for flexibility, enclosed in a rubber or silicon hose that allows continuous water circulation to remove heat during operation.

The Crucial Function: Why Cables Need Cooling

An induction furnace operates by running extremely high currents (often thousands of amperes) through a copper coil to generate a powerful electromagnetic field, which in turn heats and melts the metal charge. This massive current flow generates significant heat in the cables connecting the power supply to the induction coil.

The primary function of a water-cooled cable is heat dissipation.

- Prevent Overheating: Without active cooling, the cable’s high temperature would rapidly degrade the insulation and conductor material, leading to reduced efficiency, power loss, and catastrophic failure.

- Maintain Electrical Efficiency: As temperature rises, the electrical resistance of the copper conductor increases. By keeping the cables cool, their resistance is minimized, which is vital for low energy loss and maximizing the power delivered to the induction coil.

- Ensure Safety and Longevity: Effective cooling prolongs the cable’s lifespan and mitigates the risk of insulation breakdown, fire hazards, and system shutdowns, thereby enhancing overall operational safety and reliability.

- Prevent Overheating: Without active cooling, the cable’s high temperature would rapidly degrade the insulation and conductor material, leading to reduced efficiency, power loss, and catastrophic failure.

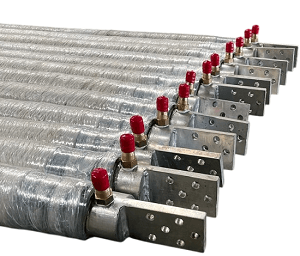

Types of Water-Cooled Cable Connections

- Flat–Flat Type – Both ends have flat terminals for bolted connections. Mainly used by Electrotherm and Megatherm

- Flat–Nut Type– One end has a flat terminal and the other has a threaded nut connection. Mainly used by Electrotherm

- Nut–Nut Type– Both ends feature threaded nut connections for secure tightening. Mainly used by Inductotherm

- Flat–Flange Type– One end has a flat terminal, while the other connects through a flange Fitting. Mainly used by Electrotherm

Why Choose Electro Power Enterprise for Water-Cooled Cables?

At Electro Power Enterprise, we manufacture and supply high-quality water-cooled cables designed for induction furnace applications of all capacities. Our cables are built with premium-grade copper conductors, reinforced insulation, and durable hose materials to ensure long service life and reliable current transmission.

We also provide customized lengths, connectors, and spare parts to suit your furnace model. Whether you need coil repair, bus bars, or power supply components, our team delivers genuine spare parts with proven performance and durability.

Contact Us

Upgrade your induction furnace with reliable and efficient water-cooled cables.

Call us at +91 76003 43075 or connect with our experts for professional support and genuine furnace parts

Also Read: Why Water-Cooled Cables are Critical for Your Induction Furnace

With over 7 years of hands-on experience in the induction furnace industry, Harsh Baraiya holds a Master’s degree in Power Electronics from Vellore Institute of Technology (VIT). He possesses in-depth knowledge of induction furnace design, operation, and maintenance, and shares practical insights to help engineers and plant professionals enhance furnace efficiency and reliability.