The Powerhouse Duo: Thyristors (SCRs) and Diodes in Your Induction Furnace

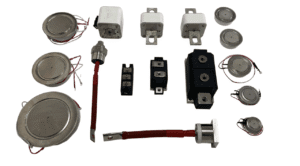

Every induction melting furnace relies on a high-frequency alternating current (AC) to generate the magnetic field that melts metal. The standard industrial power line, however, delivers low-frequency AC. The critical job of converting this power falls to the Induction Furnace Power Supply, driven by an array of specialized high-power semiconductor components: Thyristors (Silicon Controlled Rectifiers) and Diodes.

Part 1: The Diode – Your DC Power Gatekeeper

The diode is the simplest of the two, acting as a mandatory one-way street for electrical current.

- Role: The Rectifier Stage. In the first stage of the power supply (the rectifier), a bank of robust Induction Furnace Diodes converts the incoming low-frequency AC (like 50/60 Hz) into a massive DC voltage. This is often achieved using a three-phase bridge rectifier circuit.

- Key Component: Look for Converter Grade Diodes They are designed to withstand high current and voltage spikes from the main power line, ensuring the stability of the DC “bus” voltage.

- Impact: A properly functioning rectifier stage, anchored by high-quality Induction Furnace Diodes, is essential for delivering the clean, stable DC power required for the high-frequency conversion.

Part 2: The Thyristor (SCR) – The Frequency Changer

The Thyristor (or SCR in Induction Furnace applications) is a sophisticated, controllable switch. It allows current to flow only when triggered by a precise electrical pulse (the gate signal), giving the power supply its critical control element.

- Role: The Inverter Stage. This is the most demanding role. The thyristors are arranged in a high-frequency resonant inverter circuit. By switching on and off thousands of times per second, they transform the DC power back into the High-Frequency AC needed by the induction coil.

- Key Component: This stage requires Inverter Grade Thyristors (or Fast-Switching SCRs). These are specially engineered to have an extremely short turn-off time to handle frequencies often between 1 kHz and 10 kHz. Failure to switch fast enough leads to catastrophic short circuits.

- Control Element: Thyristors also allow for precise power control. By adjusting the timing (or firing angle) of the gate pulse, operators can smoothly regulate the power output of the furnace, optimizing the melting process and ensuring energy efficiency.

Critical Maintenance and Performance Factors

For anyone managing or maintaining an Induction Melting Furnace, these semiconductor components are the most sensitive. Their longevity depends entirely on two factors:

- Thermal Management (Thyristor Water Cooling): Both the SCRs and Diodes handle enormous power, generating immense heat. They must be mounted on water-cooled chill blocks to maintain their junction temperature below critical limits. A failure in the Thyristor Water Cooling system is a primary cause of burnout.

- Protection Circuits: These components are protected by SCR Diode Modules and Snubber Circuits (R-C networks) designed to absorb voltage spikes (dv/dt) and limit the rate of current rise ($di/dt$) during switching. Replacing these components with sub-standard or incorrect parts is a recipe for failure.

The Bottom Line for Furnace Efficiency

The performance of your Induction Furnace Power Supply is only as good as its semiconductors. Investing in reliable, high-specification Inverter Grade Thyristors and Converter Grade Diodes ensures maximum uptime, energy efficiency, and control over your metal-melting operation. They are small components with a monumental task.

Do you need to source replacement SCRs, Diodes, or a complete Thyristor Module for a specific model of induction furnace (e.g., Inductotherm, Electrotherm, Megatherm, etc.)?

At Electro Power Enterprise, we supply high-quality SCRs, Diodes, SCR Clamp Assemblies, and power control components designed for all types of induction furnaces.

Call us at +91 76003 43075 for genuine spare parts, expert guidance, and reliable support from India’s trusted Induction Furnace Spare Parts Manufacturer.

Also Read: Water-Cooled Cables in Induction Furnaces – Types, Function, and Common Failures

Rajesh Baraiya, Founder of Electro Power Enterprise, is passionate about making induction furnaces run more efficiently and last longer. Backed by three decades of hands-on experience, He provides practical insights into Induction furnace spare parts, enabling industries to achieve higher efficiency and longer furnace life.