Repairing of Induction Furnace High-Frequency Transformer

At Electro Power Enterprise, we specialize in repairing and refurbishing Induction Furnace High-Frequency Transformers used in all types of induction melting and heating furnaces. Our goal is to restore your transformer’s original performance, insulation strength, and reliability while reducing downtime and maintenance costs.

Repairing of Induction Furnace CLR

At Electro Power Enterprise, we specialize in Induction Furnace CLR Repair and Refurbishment Services. The Current Limiting Reactor (CLR) is a critical component in the induction furnace power supply system, designed to limit short-circuit currents, protect thyristors, and stabilize current flow during melting or heating operations.

Repairing of Induction Furnace DI/DT Reactor

At Electro Power Enterprise, we specialize in induction furnace DI/DT coil repair and refurbishment to ensure smooth and reliable operation of your induction furnace power supply system. The di/dt coil plays a vital role in controlling the rate of current change (di/dt) and protecting thyristors, rectifiers, and other electronic components from voltage spikes and short circuits.

Repairing Of Induction Coil

The induction furnace coil is the heart of your melting system. When cracks, insulation breakdown, or mechanical damage occurs, the efficiency and safety of your entire operation are immediately compromised, leading to significant induction furnace downtime. Replacing a coil is costly and time-consuming.

Repairing Of Induction Furnace Water Cooled Cable

Is your high-performance induction melting furnace suffering from an unreliable water-cooled cable? Premature failure of these critical power leads is a major cause of costly induction furnace downtime. Don’t let a damaged cable compromise your production schedule or efficiency.

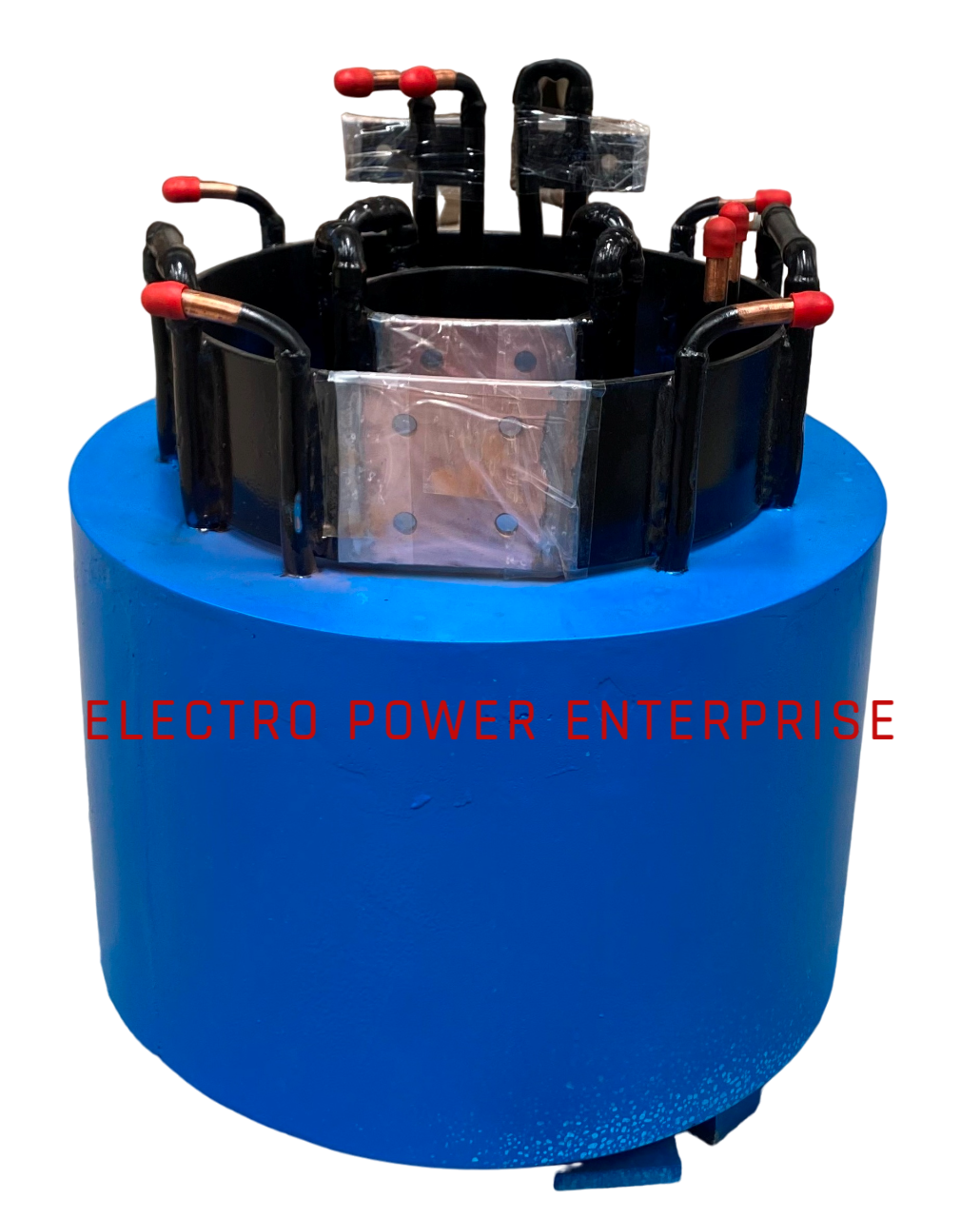

Repairing of Induction Furnace Selector Switch or Change Over Switch

The Induction Furnace Changeover Switch (or Selector Switch) is the central point of control for power distribution in multi-furnace or multi-coil systems. This high-current, high-voltage component must operate flawlessly to ensure power is accurately and safely delivered, whether you are running a single melting furnace or switching rapidly between multiple units.

Repairing of Induction Furnace Lamination Yoke

The induction furnace yoke is a vital, often overlooked, component that maintains the coil’s structural integrity and—crucially—minimizes magnetic flux loss. A damaged, corroded, or failing laminated yoke leads to stray magnetic fields, overheating, increased power consumption, and reduced induction furnace efficiency.

Repairing of Induction Furnace High-Frequency Water-Cooled Capacitor

The water-cooled capacitor bank is the electronic backbone of your induction melting furnace, crucial for power factor correction and allowing the system to operate efficiently at medium frequencies. When capacitor elements fail, they cause voltage imbalances, reduced melting capacity, and severe risk to your expensive power supply electronics.

Induction Furnace PCB Card Repair Service

At Electro Power Enterprise, we offer specialized Induction Furnace PCB Card Repair Services for Inductotherm and Electrotherm furnace systems. The PCB control cards are the heart of the furnace power supply, responsible for managing firing control, feedback, protection, and communication between components. Any fault in these cards can lead to major furnace downtime or performance instability.