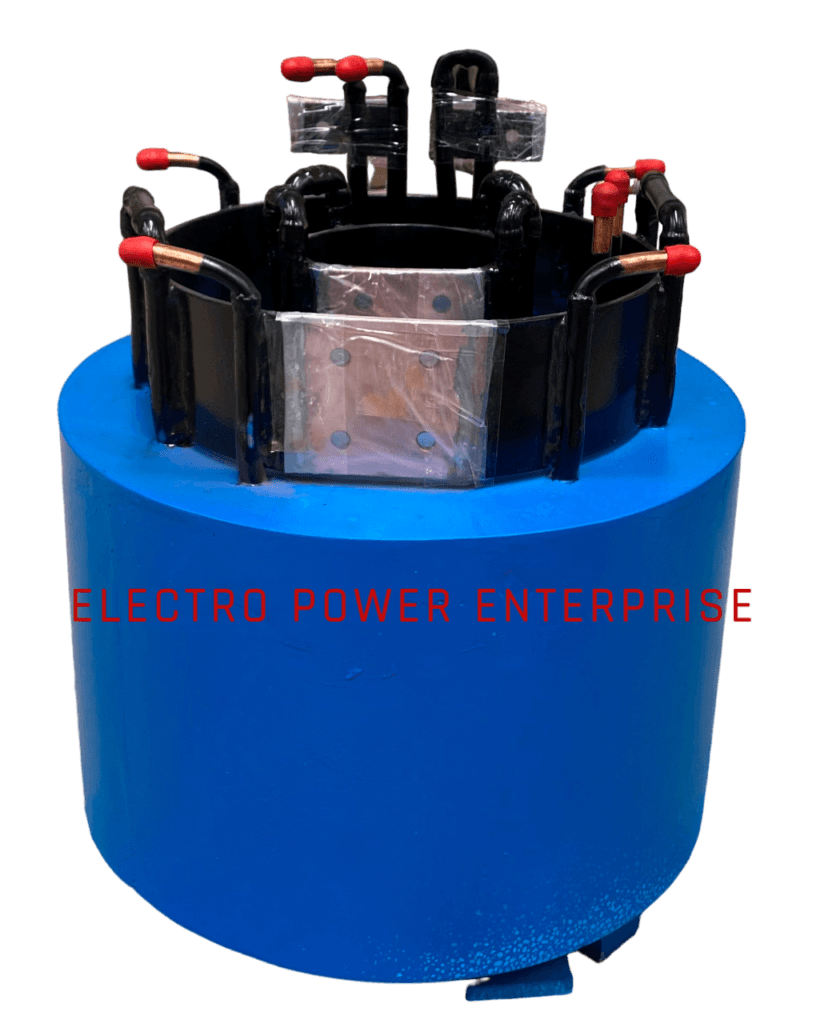

Induction Furnace High-Frequency Transformer Repair Service

Services & Support

At Electro Power Enterprise, we specialize in repairing and refurbishing Induction Furnace High-Frequency Transformers used in all types of induction melting and heating furnaces. Our goal is to restore your transformer’s original performance, insulation strength, and reliability while reducing downtime and maintenance costs.

Our Repair Process

- Inspection and Fault Diagnosis

Each transformer is carefully inspected to identify problems such as insulation breakdown, overheating, copper damage, or epoxy cracks. - Epoxy Removal and Copper Checking

The old or damaged epoxy insulation is completely removed, allowing our technicians to check each copper turn and connection. If necessary, we replace damaged copper tubes or windings using high-conductivity copper to maintain low power losses. - Re-Insulation and Epoxy Filling

After cleaning and repair, we apply high-grade PTFE, glass fiber, and epoxy insulation on both the primary and secondary sides to eliminate leakage current and ensure high dielectric strength. - Testing and Quality Verification

The repaired transformer undergoes electrical, pressure, and load testing to verify performance, inductance stability, and insulation resistance. Each unit is restored to meet OEM specifications for safe and efficient furnace operation.

Why Choose Electro Power Enterprise

- Expert team of engineers and technicians for high-frequency transformer repair

- Use of premium epoxy and insulation materials for long-life performance

- Fully equipped facility for testing and re-winding

- Fast turnaround and OEM-grade quality assurance