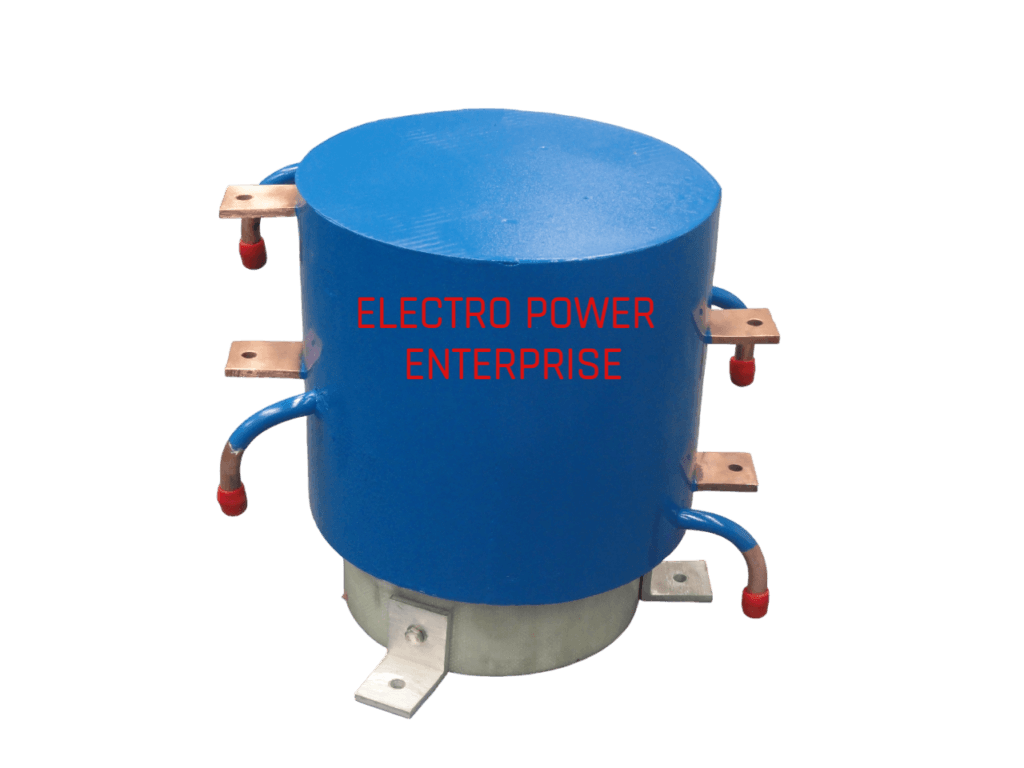

Repairing of Induction Furnace DI/DT Reactor

At Electro Power Enterprise, we specialize in induction furnace di/dt coil repair and refurbishment to ensure smooth and reliable operation of your induction furnace power supply system. The di/dt coil plays a vital role in controlling the rate of current change (di/dt) and protecting thyristors, rectifiers, and other electronic components from voltage spikes and short circuits.

Step-by-Step DI/DT Coil Repair Process

- Epoxy Removal

The first step involves carefully removing the old or damaged epoxy material from the coil. This process allows our technicians to access the internal copper turns for detailed inspection without damaging the coil structure. - Copper Turn Inspection and Replacement

Each copper turn is visually inspected for signs of overheating, corrosion, or cracking. If any turn is found defective, it is repaired or replaced using high-quality copper to restore original conductivity and performance. - Pressure and Flow Test

After repair, the di/dt coil undergoes pressure testing and water flow testing to confirm there are no leaks and that the water-cooled system is functioning properly for effective heat dissipation. - Inductance Check

The coil’s inductance value is measured and matched with the original design to ensure consistent electrical characteristics and performance in the induction furnace circuit. - Insulation and Epoxy Filling

Once all tests are passed, we provide proper insulation to all copper turns and refill the coil with high-grade epoxy resin. This ensures strong mechanical bonding, enhanced electrical insulation, and long service life.

Quality Assurance and Final Testing

Every repaired di/dt coil is tested under working conditions to ensure stable operation, correct inductance, and proper insulation resistance. The refurbished coil performs like a new component, delivering maximum reliability and efficiency in induction melting and heating furnaces.