Repairing of Induction Furnace CLR

Services & Support

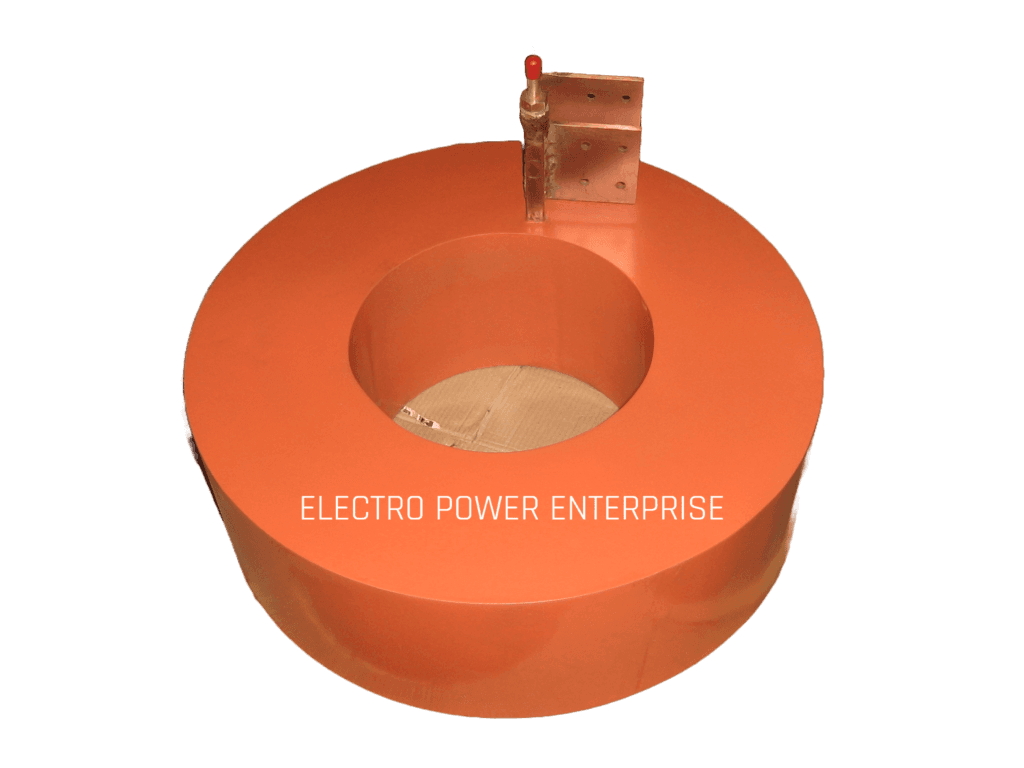

At Electro Power Enterprise, we specialize in Induction Furnace CLR Repair and Refurbishment Services. The Current Limiting Reactor (CLR) is a critical component in the induction furnace power supply system, designed to limit short-circuit currents, protect thyristors, and stabilize current flow during melting or heating operations.

Over time, the CLR may face issues like epoxy cracks, insulation failure, copper turn damage, or overheating. Our expert technicians carry out complete inspection, repair, and testing to restore the reactor’s performance to its original condition.

Our CLR Repair Process

- Inspection and Cleaning

The CLR is thoroughly inspected for mechanical damage, insulation breakdown, or overheating. All dust, carbon, and epoxy debris are cleaned before repair. - Epoxy Removal and Copper Turn Checking

The old epoxy material is carefully removed to access the copper windings. Each turn is examined for cracks or deformation. If necessary, damaged copper turns are repaired or replaced using high-quality copper conductors. - Pressure and Flow Testing (for Water-Cooled CLR)

For water-cooled CLRs, we perform pressure and water flow tests to ensure leak-free performance and proper cooling system function. - Inductance Measurement

The inductance value of the reactor is checked and calibrated to match the original design, ensuring stable and safe operation of the induction furnace circuit. - Insulation and Epoxy Re-Filling

After successful testing, new insulation layers are applied to copper turns. The CLR is then refilled with high-grade epoxy resin to provide strong electrical insulation and mechanical durability. - Final Testing and Quality Verification

Each repaired Current Limiting Reactor is tested for inductance, insulation resistance, and mechanical strength before dispatch, ensuring it meets OEM performance standards.

Why Choose Electro Power Enterprise

- Over 30 years of experience in induction furnace part repair and manufacturing

- Expertise in CLR, di/dt coil, and water-cooled cable repairs

- OEM-grade materials and epoxy insulation used in all repairs

- Comprehensive testing and certification for every refurbished unit