Low Power / Slow Melt in an Induction Furnace? Parts to Check First (Capacitors, Yokes, Cooling, Cables)

When an induction furnace takes longer than normal to melt—without any obvious breakdown—most foundries call it “low power” or “slow melt.” The mistake is to immediately suspect the power supply only. In reality, slow melting is often caused by a few common spare parts that gradually degrade: capacitors, yoke laminations, cooling components, and water-cooled cables.

This guide covers the first checks you should do, the parts most likely responsible, and how to confirm the issue before ordering spares.

Typical Symptoms of Low Power / Slow Melt

You may notice one or more of these:

- Melt time increased by 10–30% (or more)

- kW does not reach normal value / fluctuates

- More frequent trips (overheat, water flow, inverter alarms)

- Higher coil / cable temperature than usual

- Poor stirring or uneven melting

- Higher electrical consumption per heat

Confirm It’s Really “Low Power” (Not a Process Issue)

Before parts, rule out operating conditions:

- Charge material changed? (more rust, more fines, more returns)

- Charge size different? (too large pieces reduce coupling)

- Lining thickness increased? (thicker refractory increases distance from coil → slower heat transfer)

- Furnace fill level low? (coupling reduces if charge is not positioned correctly)

If these are normal and slow melt persists, move to parts.

1) Capacitors & Capacitor Bank Parts (Most Common Cause)

In many induction systems, capacitor health directly impacts power factor, resonance stability, and delivered kW.

What fails in capacitor banks

- Capacitor value drift (capacitance reduces over time)

- Heating / swelling of capacitors

- Loose busbar joints causing voltage drop

- Failed contactors, fuses, or balancing resistors

- Cooling fan failure inside capacitor room/panel

Quick checks

- Compare kvar/kW behavior with normal heats (if your panel shows it)

- Look for hot spots on busbars, capacitor terminals, and fuse holders

- Check for bulging, leakage, discoloration, or smell

- Measure capacitance (during shutdown, safely isolated)

- Check fuse continuity and signs of fuse overheating

Spare parts to keep ready

- Capacitors (same kvar rating and voltage class)

- Capacitor fuses, discharge resistors

- Contactor/relay spares

- Copper flexible links / lugs / hardware kits

Tip: Many “low power” cases are simply one capacitor stage weak or isolated, reducing total kvar and increasing melt time.

2) Yoke Laminations (CRGO/CRNGO) & Yoke Clamping Hardware

The yoke’s job is to guide the magnetic flux and reduce stray losses. When yokes degrade or loosen, energy is wasted as heat in unwanted areas.

Common yoke-related issues

- Loose yoke clamping or broken fasteners

- Wrong grade or mixed laminations (CRGO/CRNGO mismatch)

- Rust and gaps between laminations (poor stacking)

- Shifted yoke position—air gaps increase loss

- Overheating due to poor cooling/ventilation

Quick checks

- Look for hot yoke areas (infrared gun helps)

- Check mechanical tightness of yoke packs and clamps

- Inspect for burn marks, vibration wear, or misalignment

Spares / maintenance items

- Yoke clamping bolts, insulation sheets, spacers

- Correct grade laminations (as per your furnace design)

- Yoke cooling arrangements (if applicable)

Result: Fixing yokes doesn’t always increase power instantly, but it reduces losses and improves overall efficiency and stability.

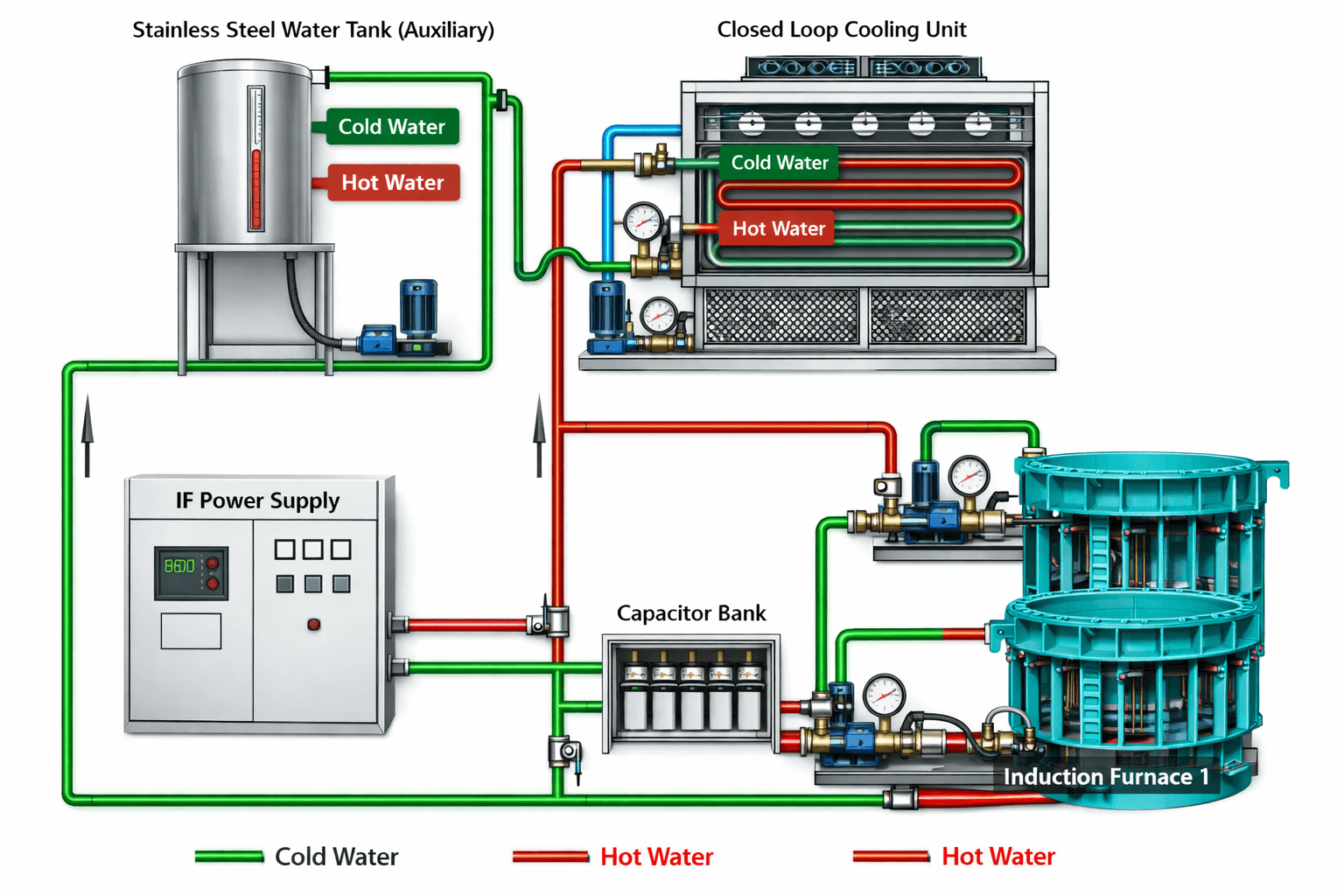

3) Cooling System Parts (Flow, Scale, Blockages) — Hidden Power Killer

Cooling doesn’t “create” power, but poor cooling forces derating and causes trips. Also, overheating in coil/cables increases resistance and losses.

Parts to check first

- Flow switches / sensors (false low-flow)

- Strainers and filters (partly blocked)

- Chill blocks / manifolds (scaling, blockage)

- Hoses collapsing internally or leaking

- Heat exchanger performance (high inlet water temp)

Quick checks

- Verify actual flow rate and pressure (not only sensor status)

- Compare inlet/outlet temperature difference (ΔT)

- Look for scale inside hoses/manifolds

- Ensure cooling water temperature is within your normal range

Spares to keep ready

- Flow switch, temperature sensor, hose kit

- Chill block seals/gaskets

- Strainer elements, O-rings, clamps

Tip: Even a small reduction in flow can raise copper temperature, increasing losses and causing “slow melt” that looks like low power.

4) Water-Cooled Cables, Flexible Links & Busbar Joints

Water-cooled cables and flexible links carry huge current. If they develop resistance, you lose power as heat before it reaches the coil.

What goes wrong

- Internal tube choking (scale/rust)

- Poor crimps or loose lugs

- Partial strand break inside flexible leads

- Carbonization or arcing marks at joints

- Wrong replacement cable size (cross section too low)

Quick checks

- Feel/measure temperature rise at both ends during operation

- Check lug bolts for loose joints

- Look for discoloration, burning, green corrosion

- Inspect water fittings and flow through the cable

Spares to keep ready

- Water-cooled cable assemblies (correct length + lug size)

- Lug kits, copper braid links, insulation sleeves

- Water fittings, seals, and clamps

Rule: If a connection is hot, it’s wasting power. Hot joints are “power thieves.”

5) Coil Condition & Coil Insulation (If Slow Melt Is Severe)

Coil issues typically show as trips, leakage, or arcing, but early stages can appear as reduced efficiency.

Check for:

- Turn-to-turn heating marks

- Insulation breakdown (mica/syndanio/FRP supports)

- Coil deformation creating uneven coupling

- Water leakage micro-cracks affecting cooling

Spare parts: coil insulation sheets, supports, copper jumpers, repair kits—plus planned coil repair.

Quick Diagnostic Order (Fastest Way)

If you want the fastest “first response” checklist:

- Check water flow & cooling ΔT (filters, strainers, flow switch accuracy)

- Check hot joints (water-cooled cables, flex links, busbars)

- Inspect capacitor bank (bulging, fuses, loose terminals, hot spots)

- Inspect yoke tightness & heating

- Inspect coil condition (only after the above)

When You Should Stop and Call for Support

Stop troubleshooting and get qualified electrical/hydraulic help if:

- You see arcing marks in the power circuit

- Repeated inverter/rectifier trips occur

- Capacitors show swelling/leakage

- Water flow is unstable or leaking near electrical areas

FAQ: Low Power / Slow Melt in Induction Furnace

Q1. Can one failed capacitor reduce melting speed?

Yes. A weakened stage can reduce overall reactive support, destabilize tuning, and reduce usable kW.

Q2. Do yokes affect melting speed?

Indirectly, yes—poor yokes increase losses and heat, and reduce efficiency.

Q3. Why are cables so important?

High resistance joints waste power as heat. You pay for kW that never reaches the coil.

Need Expert Help with Low Power or Slow Melt?

Talk to our induction furnace specialists for quick diagnosis, spares guidance, and on-site support.

📞 Call: +91 7600 343 092

✉️ Email: info@electropowerenterprise.in

Rajesh Baraiya, Founder of Electro Power Enterprise, is passionate about making induction furnaces run more efficiently and last longer. Backed by three decades of hands-on experience, He provides practical insights into Induction furnace spare parts, enabling industries to achieve higher efficiency and longer furnace life.