Induction Furnace Top and Bottom Block – Function, Material, and Importance

Introduction

In an induction furnace, every component plays a vital role in ensuring efficient and reliable melting performance. Among these, the Top and Bottom Blocks are key refractory components that provide mechanical strength, thermal insulation, and electrical safety inside the furnace coil assembly.

At Electro Power Enterprise, we supply high-quality induction furnace top and bottom blocks designed for maximum durability, heat resistance, and long service life — ensuring smooth furnace operations in demanding foundry environments.

What is a Top and Bottom Block in an Induction Furnace?

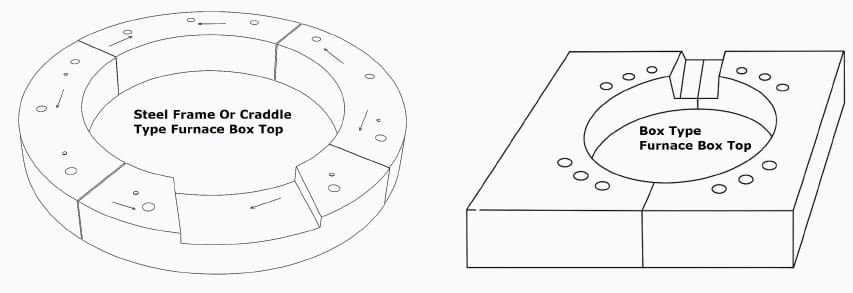

The Top Block and Bottom Block are specially designed refractory blocks positioned at the upper and lower ends of the induction furnace crucible.

- The Bottom Block supports the hearth and molten metal, acting as the base of the coil and crucible area.

- The Top Block provides a secure closure at the upper end, ensuring mechanical strength and sealing of the furnace lining.

Together, these blocks protect the furnace coil and maintain proper alignment of the refractory lining, ensuring uniform melting and minimizing energy losses.

Functions of Induction Furnace Top and Bottom Blocks

1. Thermal Insulation:

They resist extreme heat and protect the furnace coil from direct exposure to molten metal temperatures.

2. Electrical Insulation:

Prevents current leakage from the copper coil to the refractory lining, ensuring operator safety and electrical efficiency.

3. Mechanical Support:

The blocks hold the coil and crucible structure firmly, maintaining shape during thermal expansion and contraction.

4. Protection Against Metal Leakage:

The bottom block design minimizes the risk of molten metal leakage, preventing coil damage and costly downtime.

Material Used for Top and Bottom Blocks

The refractory material used for manufacturing top and bottom blocks is chosen based on thermal conductivity, strength, and dielectric properties. Common materials include:

- High-Alumina Refractory

- Silica-based Refractory

- Magnesia and Spinel Refractory

- Special Castables and Insulating Compounds

These materials provide excellent thermal shock resistance, high dielectric strength, and long operational life under extreme furnace conditions.

Key Benefits of Quality Refractory Blocks

- Reduced maintenance and downtime

- Extended furnace coil life

- Improved power efficiency

- Better thermal performance

- Enhanced safety and reliability

Why Choose Electro Power Enterprise?

At Electro Power Enterprise, we manufacture and supply precision-engineered induction furnace top and bottom blocks compatible with Inductotherm, Electrotherm, Megatherm and all major furnace brands.

Our refractory solutions are tested for high-temperature endurance, accurate fitment, and long-term stability, making us a trusted induction furnace spare parts supplier in India and abroad.

Conclusion

The top and bottom refractory blocks are crucial components for maintaining the performance, safety, and lifespan of an induction furnace. Choosing the right refractory quality ensures better thermal management and minimal breakdowns.

For durable and precisely designed induction furnace top and bottom blocks, contact Electro Power Enterprise — your trusted partner in furnace spare parts and coil insulation solutions.

Rajesh Baraiya, Founder of Electro Power Enterprise, is passionate about making induction furnaces run more efficiently and last longer. Backed by three decades of hands-on experience, He provides practical insights into Induction furnace spare parts, enabling industries to achieve higher efficiency and longer furnace life.