Induction Furnace Switch (Selector Switch) Explained: Working, Types, and Critical Importance

In an induction melting furnace system, the Induction Furnace Switch plays a crucial role in ensuring safe, smooth, and uninterrupted furnace operation. Whether you are operating a steel plant, foundry, or ferrous/non-ferrous melting unit, a reliable furnace switch is essential for controlling and isolating the electrical power supplied to the induction furnace.

In this blog, we explain what an induction furnace switch is, how it works, and why it is important for induction furnace safety and performance—along with SEO-focused furnace keywords.

We Manufacture Switches for Inductotherm, Electrotherm & Megatherm Furnaces

Our switches are designed and manufactured to be fully compatible with:

✔ Inductotherm Induction Furnaces

High-efficiency switches with silver-plated contacts and heavy copper terminals.

✔ Electrotherm Induction Furnaces

Reinforced insulation, robust mechanical strength, and long operating life.

✔ Megatherm Induction Furnaces

High-current performance suitable for heavy steel melting and continuous operations.

We ensure:

- Perfect fitting

- High conductivity

- Low heat generation

- Durable performance even in harsh furnace environments

This makes our switches ideal for steel plants, foundries, and non-ferrous melting units.

What Is an Induction Furnace Switch?

An Induction Furnace Switch is a heavy-duty electrical switching device used to connect, disconnect, or change the power path for the induction furnace power supply.

An Induction Furnace Switch is a heavy-duty electrical switching device used to connect, disconnect, or change the power path for the induction furnace power supply.

It is specially designed to handle high current, high voltage, and high-frequency AC power used in induction melting furnaces.

Common names used in the industry:

- Induction Furnace Main Switch

- Induction Furnace Selector Switch

- Induction Furnace Changeover Switch

- Induction Furnace ON/OFF Switch

- Furnace Main Contactor / Main Break Switch

These switches are installed between the induction furnace power supply panel, water-cooled cables, and induction coil to ensure safe power handling.

How Does an Induction Furnace Switch Work?

The switch works by mechanically or electrically opening/closing the circuit that feeds power to the furnace.

Working Process:

- AC power from the Induction Furnace Power Supply reaches the changeover switch.

- The switch directs the power through Induction Furnace Water-Cooled Cables.

- From there, power flows to the Induction Furnace Coil, generating a magnetic field.

- This magnetic field induces heat inside the metal charge, melting it efficiently and safely.

A good-quality furnace switch ensures low resistance, strong contact pressure, and minimal heat generation, making it essential for stable furnace operation.

Industrial Applications

Induction furnace switches are widely used in:

- Steel plants

- Casting foundries

- Inductotherm furnaces

- Electrotherm furnaces

- Megatherm furnaces

- Non-ferrous melting units

- High-frequency induction heating systems

Why Is the Induction Furnace Switch Important?

- Furnace Safety

It protects the operator and furnace components from electrical faults by allowing quick isolation.

- Smooth Power Transfer

Ensures stable power delivery from:

- Induction Furnace Panel

- Induction Furnace Capacitor Bank

- Water-Cooled Cables

- Furnace Coil

- Protection During Maintenance

The furnace can be safely disconnected during:

- Coil replacement

- Cable servicing

- Power supply repair

- Longer Equipment Life

Prevents arcing, overheating, and electrical damage.

Where Are Induction Furnace Switches Used?

You will commonly find them in:

- Steel plants

- Foundries

- Inductotherm furnace systems

- Electrotherm furnaces

- High-frequency induction heating setups

- Melting of ferrous and non-ferrous metals

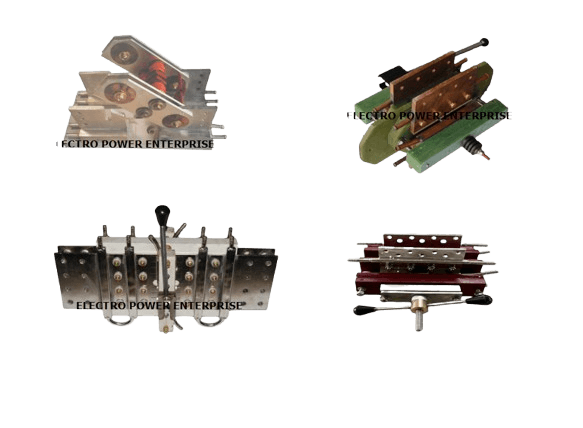

Types of Induction Furnace Switches

Manual Changeover Switch

Used to manually switch between operations or isolate the furnace.

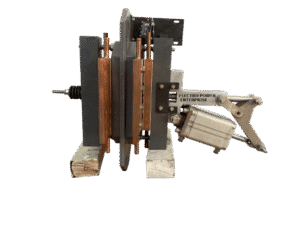

Motorized Changeover Switch

Used in large capacity furnaces for remote and automated switching.

Rotary Furnace Switch

A heavy-duty rotary mechanism that ensures reliable mechanical switching.

Vacuum or Air Break Switch

Used where safer arc suppression is required.

Key Features of a Good Induction Furnace Switch

- High current carrying capacity

- Silver-plated contact area for better conductivity

- Heat-resistant insulation

- Robust copper & brass terminals

- Low contact resistance

- Suitable for Inductotherm & Electrotherm systems

- Easy to maintain and replace

Common Applications in Furnace Systems

- Connecting power supply to furnace

- Switching between two furnaces

- Isolating coil for safety

- Protection during capacitor bank maintenance

- Emergency power cut-off

Conclusion

An Induction Furnace Switch is a vital safety and control component used in every induction melting system. It ensures proper power transfer from the furnace power supply → water-cooled cable → induction coil, making metal melting efficient, safe, and reliable.

If you are a steel plant or foundry looking for high-quality induction furnace spare parts, switches, coils, and water-cooled cables, choosing the right switch will protect your furnace and improve performance.

Rajesh Baraiya, Founder of Electro Power Enterprise, is passionate about making induction furnaces run more efficiently and last longer. Backed by three decades of hands-on experience, He provides practical insights into Induction furnace spare parts, enabling industries to achieve higher efficiency and longer furnace life.