How Does an Induction Melting Furnace Coil Work & How Metal Melts Inside It? (Complete Guide)

The induction melting furnace is a core machine used in steel plants, ferrous foundries, non-ferrous foundries, forging units, and metal recycling industries.

At the center of this technology is the induction furnace coil, the main component responsible for generating heat and melting metal without any flame.

In this guide, we explain how an induction furnace coil works, how metal melts inside an induction melting furnace, and how AC power from the induction furnace power supply / induction furnace panel flows through water-cooled cables into the coil.

1. Power Flow: From Induction Furnace Panel to Coil

Every induction melting furnace starts with an induction furnace power supply, also called the induction furnace panel.

The panel generates high-frequency AC power, specially controlled using IGBT or Thyristor converter–inverter circuits.

Flow of Power:

- AC power generated from the induction furnace power supply

- Power flows through induction furnace water-cooled cables

- These flexible copper braided cables transfer high current safely to the induction furnace coil terminals

- The coil receives this high-frequency AC and creates magnetic energy to melt metal

The water-cooled cable is important because it carries very high amperes while staying flexible enough to allow furnace tilting.

2. What Is an Induction Furnace Coil?

An induction furnace coil, often made from high-conductivity copper tubing, is the heart of the melting system.

The coil is:

- Water-cooled

- Electrically insulated

- Designed for high-frequency, high-current operation

3. How the Coil Creates a Magnetic Field

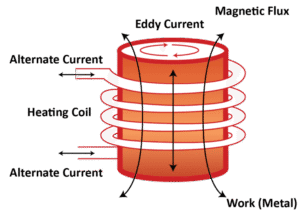

When high-frequency AC power flows from the induction furnace panel → through water-cooled cables → into the copper coil, it produces a rapidly alternating magnetic field around the crucible.

This magnetic field passes through:

- the refractory lining

- the charge material inside the crucible

The process is based on electromagnetic induction

4. How Metal Melts Inside an Induction Melting Furnace

Metal melts inside the induction furnace without touching the coil due to two heating effects:

A. Eddy Current Heating – Main Source of Heat

The magnetic field induces eddy currents inside the metal charge.

These currents circulate within the metal, and due to the natural electrical resistance of the metal, heat is generated (I²R losses).

This is the primary heat source responsible for melting steel, copper, aluminum, or any metal placed in the crucible.

B. Hysteresis Heating (For Ferrous Metals)

For magnetic metals like steel and cast iron, the magnetic field continuously re-aligns the internal magnetic domains.

This internal friction produces hysteresis heat, providing additional melting power.

5. Induction Stirring – Why Induction Furnaces Produce Cleaner Metal

As the metal starts melting, the magnetic forces inside the coil cause strong electromagnetic stirring.

This process:

- cleans the molten metal

- ensures uniform temperature

- improves chemical homogeneity

- helps alloying elements dissolve faster

- reduces cold spots

- removes gas pockets and impurities

This is why induction melting furnaces are preferred for high-quality casting, forging, and steel manufacturing.

6.Role of Water Cooling in the Coil

The coil carries extreme current, so it is always built from a hollow copper tube.

Cold water flows continuously through the tubing, preventing the coil from overheating.

Water cooling ensures:

- longer coil life

- stable insulation

- safe operation

- efficiency in melting

- protection of induction furnace spare parts

Water flow switches, pressure switches, and temperature sensors ensure safety.

7. Refractory Lining – The Insulation Between Coil & Metal

Between the coil and the metal charge, a refractory lining (ramming mass) acts as:

- thermal protection

- electrical insulation

- containment for molten metal

This prevents electrical arcs, short circuits, and coil damage.

8. Full Step-By-Step Summary (Simple Explanation)

- Induction furnace panel generates AC power

- Power flows through induction furnace water-cooled cables

- Cables supply high-frequency current to the induction furnace coil

- Coil creates a powerful alternating magnetic field

- Magnetic field induces eddy currents inside the metal

- Eddy currents generate intense heat, melting the metal

- Magnetic forces create induction stirring

- A fully molten, homogeneous metal bath is formed

Enhancing Induction Furnace Performance with Quality Components

We supply induction furnace coils, water-cooled cables, coil supports, FRP supports, Permali supports, induction furnace spare parts, hydraulic parts, PCB card repair, induction furnace panel repair, Inductotherm spare parts, Electrotherm spare parts, high-frequency transformers, and on-site furnace repair services for all types of induction melting furnaces.

Contact us today to enhance furnace performance, reduce downtime, and ensure efficient, safe melting

Rajesh Baraiya, Founder of Electro Power Enterprise, is passionate about making induction furnaces run more efficiently and last longer. Backed by three decades of hands-on experience, He provides practical insights into Induction furnace spare parts, enabling industries to achieve higher efficiency and longer furnace life.