Low Power / Slow Melt in an Induction Furnace? Parts to Check First (Capacitors, Yokes, Cooling, Cables)

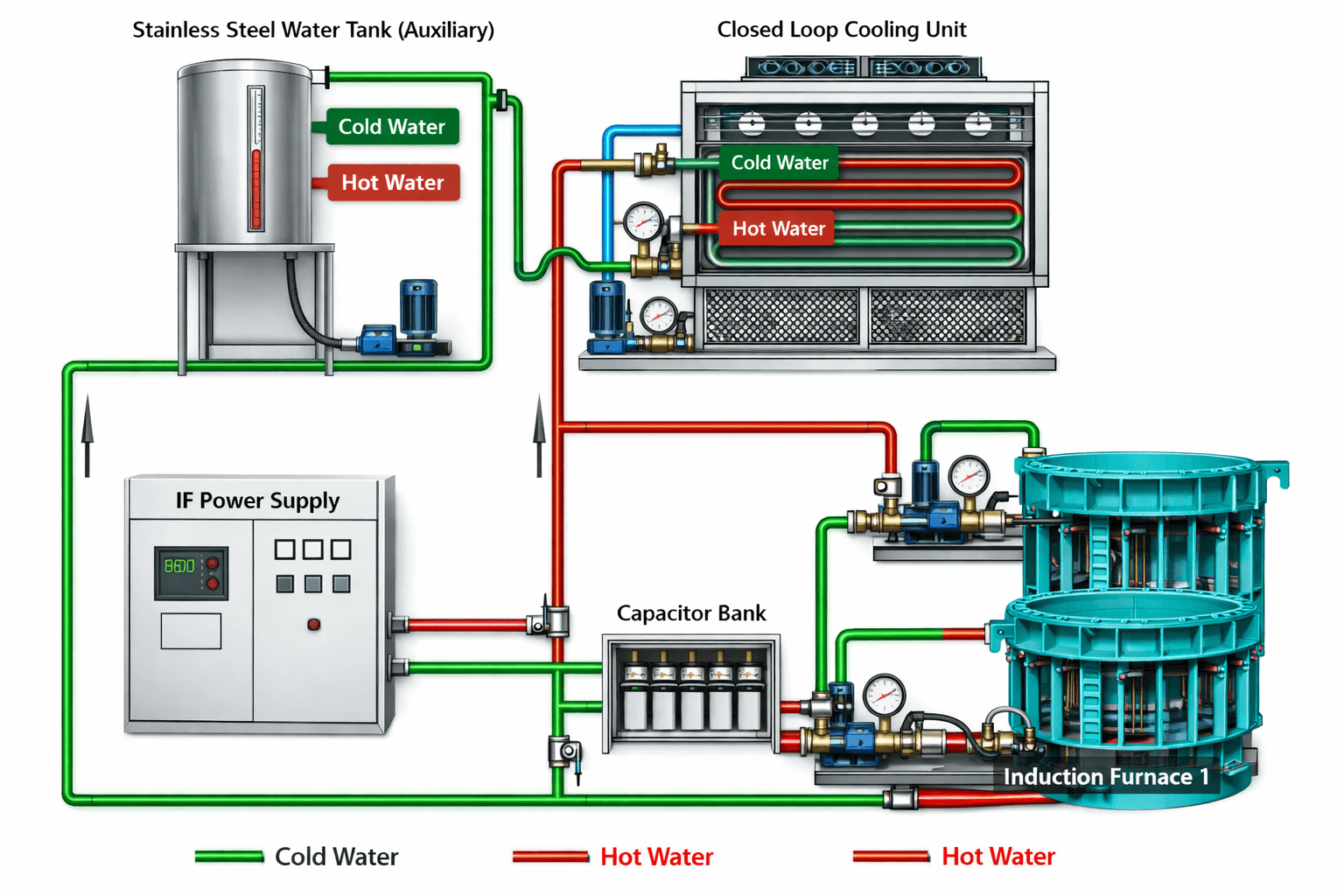

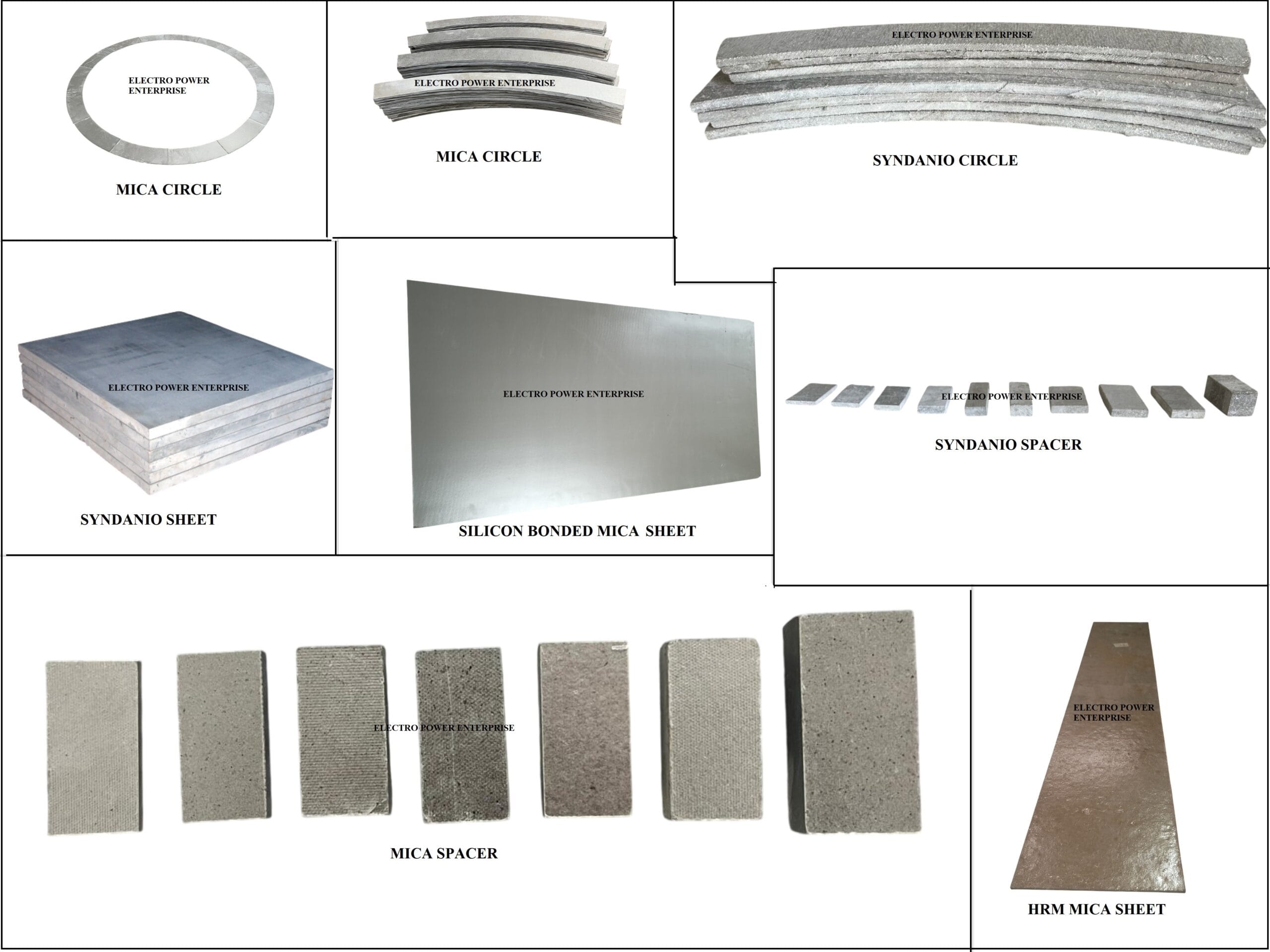

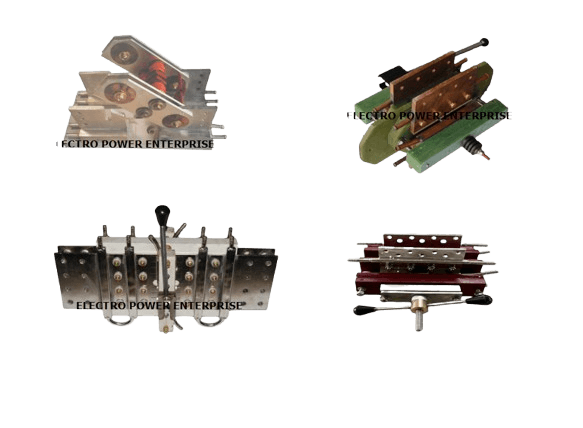

When an induction furnace takes longer than normal to melt—without any obvious breakdown—most foundries call it “low power” or “slow melt.” The mistake is to immediately suspect the power supply only. In reality, slow melting is often caused by a few common spare parts that gradually degrade: capacitors, yoke laminations, cooling components, and water-cooled cables. […]