Dissecting the Induction Furnace: A Deeper Look at Induction Furnace Spare Parts

- Function: Converts incoming utility power (typically 3-phase, low frequency) into the high-frequency, high-power AC current required by the induction coil. It controls the furnace’s power output and operating frequency.

- Key Sub-components:

- Rectifier: Converts AC input to DC. Uses diodes or SCRs (Silicon Controlled Rectifiers) for controlled rectification.

- DC Link Reactor/Capacitors: Smooths the DC voltage and provides energy storage.

- Inverter: This is the core of modern power supplies. Uses high-power semiconductor devices (like IGBTs – Insulated Gate Bipolar Transistors, or GTOs – Gate Turn-Off Thyristors) to convert DC back into high-frequency AC. This is where the operating frequency is generated.

- Output Transformer (Optional/Depending on Design): Matches the impedance of the coil to the inverter output.

- Capacitor Bank (Resonant Bank): Crucial for power factor correction and creating a resonant circuit with the induction coil. The coil is inductive, and the capacitors provide reactive power to achieve a near-unity power factor, minimizing reactive power draw from the grid and maximizing efficiency. This is often tunable to match the changing impedance of the coil as the metal melts.

- Control Circuitry: Microprocessor-based controllers monitor furnace parameters, manage power output, frequency, and safety interlocks.

- Design Considerations:

- Power Rating (kVA/MW): Determines the furnace’s melting capacity and speed.

- Frequency Range: Dictates the type of melting (Mains, Medium, High).

- Efficiency: Modern solid-state power supplies are highly efficient.

- Harmonic Mitigation: Includes filters to reduce harmonic distortions fed back into the grid, which can cause issues for other electrical equipment.

- Interdependency: The most complex and expensive component. Drives the Induction Coil, requires input from the Cooling System, and is controlled by automation systems. Directly impacts the furnace’s Electrical Efficiency and Power Ratings.

5. Refractory Linings & Insulation

- Material types: Rammed, castable, or crucible-based refractory, including mica and phlogopite insulation to protect coils and structural panels

- Failure modes: Erosion, spalling, heat-shock cracks, and thinning that expose coils.

- Inspection & renewal: Daily lining checks, non-destructive thickness measurement, prompt relining when worn. Stock matching replacement bricks or castables to allow fast turnarounds.

6. Switches, Breakers & Circuit Boards

- Components: MCCBs, contactors, change-over switches, and PCB modules in the power/inverter panel.

- Failure issues: Arcing, tripping, corrosion, mechanical fatigue, and obsolescence.

- Strategy: Keep high-quality OEM or equivalent switchgear, maintain circuit board inventory, and track component lifecycle for proactive replacement.

7. Support & Clamping Assemblies

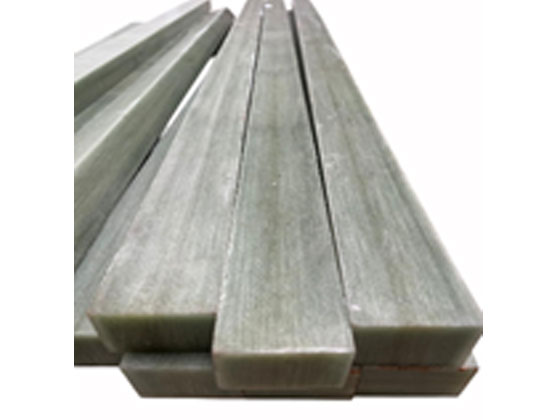

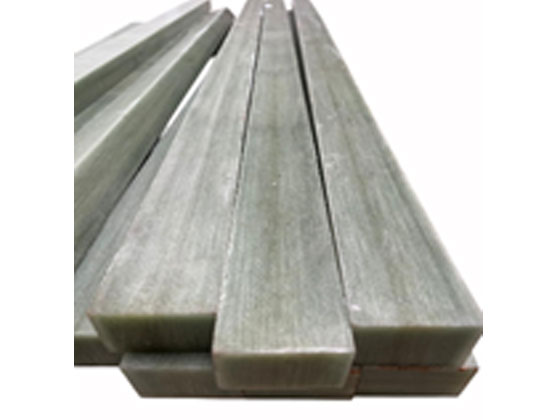

- Structural role: FRP supports, yoke clamps, hydraulic jacks, and vertical tie-rod systems hold coils firmly.

- Risks: Vibration fatigue, electromagnetic loosening, or misalignment causing coil distortion.

- Mitigation: Regular torque checks, re-tensioning tie-rods, and replacing worn supports. Stock spare FRP pads and clamp hardware to ensure safe coil positioning.

8. Cooling System & Ancillary Support

- Function: Circulates cooling water through the induction coil, power cables, and often power supply components (like IGBTs, capacitors) to dissipate the heat generated by electrical resistance.

- Components:

- Water Pumps: Circulate de-ionized or distilled water (to prevent conductivity) at specific flow rates and pressures.

- Heat Exchangers: Transfer heat from the furnace’s cooling water circuit to a secondary cooling medium (e.g., raw cooling tower water or ambient air via radiators).

- Reservoir/Tank: Holds the cooling water.

- Filters: Remove particulate matter from the cooling water.

- Flow and Temperature Sensors: Monitor the cooling water parameters to ensure proper operation and trigger alarms/shutdowns if limits are exceeded.

- Deionization System: Maintains the purity of the cooling water, especially critical for direct contact with electrical components.

- Design Considerations:

- Flow Rate and Pressure: Must be sufficient to prevent overheating of components, especially the coil.

- Water Quality: Pure, de-ionized water is essential to prevent scaling and to maintain high electrical resistivity.

- Redundancy: Often includes redundant pumps for reliability, as cooling system failure can lead to rapid and catastrophic furnace damage.

- Interdependency: Absolutely vital for the safe operation of the Induction Coil and Power Supply Unit. Failure here leads to immediate shutdown.

9. Tilting Mechanism

- Function: Allows the furnace body to tilt, enabling precise pouring of molten metal into ladles, molds, or other processing equipment.

- Mechanism:

- Hydraulic Cylinders: The robust actuators that physically lift, tilt, and lower the furnace body.

- Hydraulic Pumps: Generate the necessary fluid pressure to operate the cylinders.

- Hydraulic Hoses & Fittings: The network of conduits that safely contain and direct the high-pressure hydraulic fluid.

- Control Valves: Precisely regulate the flow and direction of the hydraulic fluid, enabling controlled tilting.

- Design Considerations:

- Stability: Must ensure smooth, controlled tilting without jarring or instability.

- Load Capacity: Capable of tilting the full weight of the furnace body plus molten metal.

- Precision Control: Allows for fine adjustment of the pouring stream.

- Safety Interlocks: Prevents tilting if conditions are unsafe (e.g., lid open, power on without melt).

- Interdependency: Mechanically connected to the Furnace Body. Controlled by the overall automation system.

Summary

Investing in high-quality induction furnace spare parts isn’t just preventive—it’s strategic. You’ll keep production rolling, avoid emergency repairs, and extend your furnace’s lifespan. For more on sourcing premium coils, capacitors, cooling systems, and tribal electronic modules, we’re here to help.

From the electrifying, high-efficiency the induction coils to the resilient, steadfast embrace of the crucibles, and the meticulous ballet performed by power supply modules and cooling systems, every single component is not merely vital, but indispensable. This deep dive into their critical functions will reveal how proactive maintenance and timely replacement aren’t just good practices, but the absolute keys to unlocking unwavering operational efficiency, paramount safety, and an extended, fruitful life for your invaluable equipment.

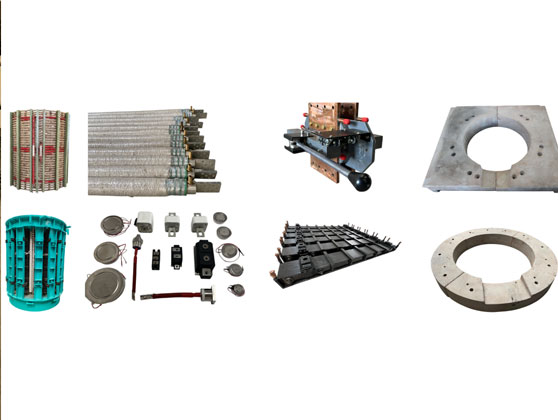

Indeed, these magnificent induction furnaces are the unwavering workhorses of foundries, steel plants, and metal-processing units across the globe—each melt a testament to their unparalleled precision, blistering speed, and remarkable energy savings. To truly master this metallurgical ballet, keeping the right arsenal of spare parts on hand isn’t just a smart strategy; it’s a non-negotiable commitment to minimizing costly downtime, elevating safety standards, and perpetually optimizing your melting efficiency. So, let’s unlock the vital components your induction furnace spare parts inventory absolutely must include to ensure continuous, reliable, and utterly dependable operation:

1. Induction Furnace Coils & Copper Turns

- Function: This is the primary component responsible for generating the rapidly alternating magnetic field that induces eddy currents in the metal charge. It’s the “engine” of the furnace.

- Material:

- Steel Frame: Heavy-duty fabricated steel sections form the main support structure.

- High-Purity Electrolytic Copper Tubing: Copper is chosen for its extremely high electrical conductivity, minimizing resistive losses (I2R) within the coil itself. It’s typically tubular to allow for internal cooling.

- Insulation: Each turn of the copper coil must be electrically insulated from its neighbors and from the crucible/furnace structure. This is crucial to prevent short circuits and ensure the entire voltage applied by the power supply is across the coil. Materials include high-temperature, arc-resistant insulating tapes (e.g., fiberglass, mica, or specialized ceramics) and sometimes epoxy encapsulation.

- Design Considerations:

- Number of Turns: Affects the inductance of the coil and the strength/penetration of the magnetic field. More turns generally mean a higher inductance and stronger field for a given current, but also higher impedance.

- Coil Diameter and Height: Optimized to provide efficient magnetic coupling with the expected charge size and shape.

- Turn-to-Turn Spacing: Critical for insulation and for allowing cooling water channels.

- Cooling Channels: Essential to prevent the copper coil from overheating due to its own I2R losses. Water is continuously circulated through the copper tubing.

- Interdependency: Directly linked to the Power Supply Unit (determines frequency and power), the Cooling System (prevents coil meltdown), and the Crucible (its geometry must fit within the coil and allow efficient coupling)

2. Furnace Body/Structure

- Function: Provides the structural support for the induction coil, crucible, tilting mechanism, and safety features. It isolates the high-voltage components and contains any potential melt spills.

- Material:

- Steel Frame: Heavy-duty fabricated steel sections form the main support structure.

- Non-Magnetic Sections (Near Coil): Areas immediately adjacent to the coil often use non-magnetic stainless steel or non-metallic materials (e.g., fiberglass reinforced plastic) to avoid inductive heating of the structure itself.

- Insulation: Thermal insulation (e.g., ceramic fiber blankets) is placed between the coil and the outer steel shell to minimize heat loss and protect personnel.

- Design Considerations:

- Robustness: Must withstand the weight of molten metal and the dynamic forces during tilting.

- Electrical Isolation: Ensures no electrical contact between the coil and the outer metal structure or ground.

- Containment: Designed to safely contain molten metal in case of a crucible failure (a “run-out pit” or safety catch basin beneath the furnace).

- Interdependency: Houses all the other components. Integral to safety features like the Tilting Mechanism.

3.Water-Cooled Cables & Hoses

- Design & materials: Comprised of annealed ETP-grade copper ropes bundled inside carbon-free rubber hoses, reinforced with fire-resistant fibers

- Cooling passages: Some include internal stainless steel water passages to ensure consistent cooling

- Pressure ratings: Typically operate at 10–20 bar.

- Failure modes: Ruptures, kinks, hose aging, and copper head failures due to thermal cycling or mechanical stress.

- Maintenance tips: Monitor hose condition and replace aged components; pressure-test yearly; check for corrosion at copper lugs.

4. Power Supply Unit (The Brain and Brawn)

- Function: Converts incoming utility power (typically 3-phase, low frequency) into the high-frequency, high-power AC current required by the induction coil. It controls the furnace’s power output and operating frequency.

- Key Sub-components:

- Rectifier: Converts AC input to DC. Uses diodes or SCRs (Silicon Controlled Rectifiers) for controlled rectification.

- DC Link Reactor/Capacitors: Smooths the DC voltage and provides energy storage.

- Inverter: This is the core of modern power supplies. Uses high-power semiconductor devices (like IGBTs – Insulated Gate Bipolar Transistors, or GTOs – Gate Turn-Off Thyristors) to convert DC back into high-frequency AC. This is where the operating frequency is generated.

- Output Transformer (Optional/Depending on Design): Matches the impedance of the coil to the inverter output.

- Capacitor Bank (Resonant Bank): Crucial for power factor correction and creating a resonant circuit with the induction coil. The coil is inductive, and the capacitors provide reactive power to achieve a near-unity power factor, minimizing reactive power draw from the grid and maximizing efficiency. This is often tunable to match the changing impedance of the coil as the metal melts.

- Control Circuitry: Microprocessor-based controllers monitor furnace parameters, manage power output, frequency, and safety interlocks.

- Design Considerations:

- Power Rating (kVA/MW): Determines the furnace’s melting capacity and speed.

- Frequency Range: Dictates the type of melting (Mains, Medium, High).

- Efficiency: Modern solid-state power supplies are highly efficient.

- Harmonic Mitigation: Includes filters to reduce harmonic distortions fed back into the grid, which can cause issues for other electrical equipment.

- Interdependency: The most complex and expensive component. Drives the Induction Coil, requires input from the Cooling System, and is controlled by automation systems. Directly impacts the furnace’s Electrical Efficiency and Power Ratings.

5. Refractory Linings & Insulation

- Material types: Rammed, castable, or crucible-based refractory, including mica and phlogopite insulation to protect coils and structural panels

- Failure modes: Erosion, spalling, heat-shock cracks, and thinning that expose coils.

- Inspection & renewal: Daily lining checks, non-destructive thickness measurement, prompt relining when worn. Stock matching replacement bricks or castables to allow fast turnarounds.

6. Switches, Breakers & Circuit Boards

- Components: MCCBs, contactors, change-over switches, and PCB modules in the power/inverter panel.

- Failure issues: Arcing, tripping, corrosion, mechanical fatigue, and obsolescence.

- Strategy: Keep high-quality OEM or equivalent switchgear, maintain circuit board inventory, and track component lifecycle for proactive replacement.

7. Support & Clamping Assemblies

- Structural role: FRP supports, yoke clamps, hydraulic jacks, and vertical tie-rod systems hold coils firmly.

- Risks: Vibration fatigue, electromagnetic loosening, or misalignment causing coil distortion.

- Mitigation: Regular torque checks, re-tensioning tie-rods, and replacing worn supports. Stock spare FRP pads and clamp hardware to ensure safe coil positioning.

8. Cooling System & Ancillary Support

- Function: Circulates cooling water through the induction coil, power cables, and often power supply components (like IGBTs, capacitors) to dissipate the heat generated by electrical resistance.

- Components:

- Water Pumps: Circulate de-ionized or distilled water (to prevent conductivity) at specific flow rates and pressures.

- Heat Exchangers: Transfer heat from the furnace’s cooling water circuit to a secondary cooling medium (e.g., raw cooling tower water or ambient air via radiators).

- Reservoir/Tank: Holds the cooling water.

- Filters: Remove particulate matter from the cooling water.

- Flow and Temperature Sensors: Monitor the cooling water parameters to ensure proper operation and trigger alarms/shutdowns if limits are exceeded.

- Deionization System: Maintains the purity of the cooling water, especially critical for direct contact with electrical components.

- Design Considerations:

- Flow Rate and Pressure: Must be sufficient to prevent overheating of components, especially the coil.

- Water Quality: Pure, de-ionized water is essential to prevent scaling and to maintain high electrical resistivity.

- Redundancy: Often includes redundant pumps for reliability, as cooling system failure can lead to rapid and catastrophic furnace damage.

- Interdependency: Absolutely vital for the safe operation of the Induction Coil and Power Supply Unit. Failure here leads to immediate shutdown.

9. Tilting Mechanism

- Function: Allows the furnace body to tilt, enabling precise pouring of molten metal into ladles, molds, or other processing equipment.

- Mechanism:

- Hydraulic Cylinders: The robust actuators that physically lift, tilt, and lower the furnace body.

- Hydraulic Pumps: Generate the necessary fluid pressure to operate the cylinders.

- Hydraulic Hoses & Fittings: The network of conduits that safely contain and direct the high-pressure hydraulic fluid.

- Control Valves: Precisely regulate the flow and direction of the hydraulic fluid, enabling controlled tilting.

- Design Considerations:

- Stability: Must ensure smooth, controlled tilting without jarring or instability.

- Load Capacity: Capable of tilting the full weight of the furnace body plus molten metal.

- Precision Control: Allows for fine adjustment of the pouring stream.

- Safety Interlocks: Prevents tilting if conditions are unsafe (e.g., lid open, power on without melt).

- Interdependency: Mechanically connected to the Furnace Body. Controlled by the overall automation system.

Summary

Investing in high-quality induction furnace spare parts isn’t just preventive—it’s strategic. You’ll keep production rolling, avoid emergency repairs, and extend your furnace’s lifespan. For more on sourcing premium coils, capacitors, cooling systems, and tribal electronic modules, we’re here to help.

Rajesh Baraiya, Founder of Electro Power Enterprise, is passionate about making induction furnaces run more efficiently and last longer. Backed by three decades of hands-on experience, He provides practical insights into Induction furnace spare parts, enabling industries to achieve higher efficiency and longer furnace life.